|

GM

|

|

« Reply #120 on: December 24, 2013, 09:49:12 AM » |

0

|

Here ya go |

|

|

|

|

Logged

Logged

|

Upon the hill there stood a cow.

It must have moved, It's not there now.

|

|

|

|

fcwrangler

|

|

« Reply #121 on: December 24, 2013, 11:19:08 AM » |

0

|

Front doors are not the problem, there is enough clearance as your picture shows, it's the rear doors that are the hassle, the gap between the door and the pillar and the opening radius are the concern. I've got an old door that I will cut up and fit it up with the top hinge and see what happens from there. Another week to recover from the hernia and I can do some light stuff with help from my son. As I have said before, I'm not in a real hurry to get things done, so this is the best time to get it all sorted out.

Jim

|

|

|

|

|

Logged

Logged

|

on the seventh day: God Made Holden

|

|

|

|

NES304

|

|

« Reply #122 on: December 28, 2013, 12:22:46 AM » |

0

|

Looks like the bend is ok and won't fowl. Have no idea how the hell I can tighten the nut once inside the pillar...  |

|

|

|

|

Logged

Logged

|

|

|

|

|

FCRB26

|

|

« Reply #123 on: December 28, 2013, 07:06:20 AM » |

0

|

cut a plate 50x50 drill a hole in the centre weld a nut onto it chop a square where u want it in the pillar and weld away..

|

|

|

|

|

Logged

Logged

|

|

|

|

|

NES304

|

|

« Reply #124 on: December 28, 2013, 08:49:19 AM » |

0

|

cut a plate 50x50 drill a hole in the centre weld a nut onto it chop a square where u want it in the pillar and weld away..

Plus the ones for the seat belts.... Was hoping not to make a mess! |

|

|

|

|

Logged

Logged

|

|

|

|

Old_Mt_Isa_Boy

qld-club

Senior Member

Offline Offline

Model: FC

Posts: 953

My Ute

|

|

« Reply #125 on: December 28, 2013, 09:21:53 AM » |

0

|

I'm still with Haydn and have a 30-30mm deep and say the width of door frame wide recess with captive nut behind that in the door to allow some sideways movement of cable.

Regards

Wayne b

|

|

|

|

|

Logged

Logged

|

|

|

|

|

fcwrangler

|

|

« Reply #126 on: December 28, 2013, 10:32:42 AM » |

0

|

The plan was as Pete said, make a plate weld a nut on then weld to the pillar and screw in. The other worry is when the door shuts, will the loom intrude on the window runner. Looking at the inner frame, I might be able to weld in a small deflector plate so the tube will miss the window. (The advantage of having the outer skins off)

Jim

|

|

|

|

|

Logged

Logged

|

on the seventh day: God Made Holden

|

|

|

|

NES304

|

|

« Reply #127 on: December 28, 2013, 11:52:29 AM » |

0

|

How will it exit neatly at the bottom then???

|

|

|

|

|

Logged

Logged

|

|

|

|

Old_Mt_Isa_Boy

qld-club

Senior Member

Offline Offline

Model: FC

Posts: 953

My Ute

|

|

« Reply #128 on: December 28, 2013, 12:17:08 PM » |

0

|

Maybe the tail behind the kicker

|

|

|

|

|

Logged

Logged

|

|

|

|

|

NES304

|

|

« Reply #129 on: December 28, 2013, 09:44:22 PM » |

0

|

I meant from the B pillar???

|

|

|

|

|

Logged

Logged

|

|

|

|

|

fcwrangler

|

|

« Reply #130 on: December 29, 2013, 10:50:44 AM » |

0

|

Look back through the rebuild, when I replaced the sills I ran conduit from the "A" pillar along the sill to the bottom of the "B" pillar and ran a draw wire through. A bit of forward planing goes a long way.

Jim

|

|

|

|

|

Logged

Logged

|

on the seventh day: God Made Holden

|

|

|

|

fcwrangler

|

|

« Reply #131 on: December 31, 2013, 12:05:50 PM » |

0

|

PROBLEM SOLVED. Many thanks to Wayne(old mt isa boy) for sending down his old loom, a bit on the large side 24"x 3/4", but for testing it has worked out fine. The ones I will be using are 12"x 1/2" so they will be a bit different to the one in the photos. It took around 1/2 an hour to set up as follows. door cut out fitted to pillar and drilled and reemed out  bolted loom to door but just pushed the end into the pillar   shut the door to check clearance  opened and closed a few times to make sure it was moving ok and presto!! it works. Just waiting for my son to cut the front door down and I will do the same and see how it goes. Will keep you posted, Jim |

|

|

|

|

Logged

Logged

|

on the seventh day: God Made Holden

|

|

|

|

NES304

|

|

« Reply #132 on: December 31, 2013, 01:40:28 PM » |

0

|

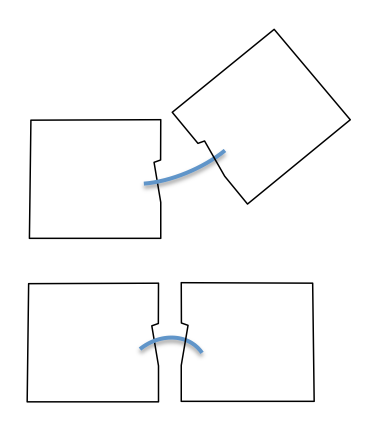

Looks great. Just had a little look on mine and that looks like it may be near the window channel. Will have to do mine lower I think.

At least we know it won't pinch now!

|

|

|

|

|

Logged

Logged

|

|

|

|

|

john253a

|

|

« Reply #133 on: December 31, 2013, 03:06:58 PM » |

0

|

Have you tryed a rivnut or nutsert

And screw the gland into that

|

|

|

|

|

Logged

Logged

|

Good + Fast = Not Cheap

Cheap + Fast = Not Good

Good + Cheap = Not Fast

|

|

|

|

fcwrangler

|

|

« Reply #134 on: December 31, 2013, 06:59:52 PM » |

0

|

Marc, this was just a mock up to see if it would work. The real thing will be just above the stay strap but the position of the hole is as far across as can be done, as the nut is hard up against the inner frame. I am looking at fitting a hose to the end of the anchor flange to keep it away from the window. The front will be in the depression above the lower hinge.

John, the anchor is about 16mm, I don't think they have them that large so I'll be making plates with nuts welded to them and then fit them into the pillars and then screw the anchors home.

As I said earlier, I will mock up the front door as well and make sure it works before I do the good doors

|

|

|

|

|

Logged

Logged

|

on the seventh day: God Made Holden

|

|

|

|

fcwrangler

|

|

« Reply #135 on: January 03, 2014, 09:12:52 AM » |

0

|

back to the drawing board!!!! did the test fitup on the front door, I have the loom fitted and opened the door to find the loom kinks up in the fully open position as the photos will show. Wayne and Haydn are correct, it would be a problem later on as each time the doors open, it will wear down the braid and cause it to fail.   I would like to keep the power to the doors, so I think for ease of fitting, I will follow JB's advise and run the wires along the door hinge. I have a couple of different idea's on how I will do this, so once again I will keep you posted on the outcome. Jim |

|

|

|

|

Logged

Logged

|

on the seventh day: God Made Holden

|

|

|

|

DJ

|

|

« Reply #136 on: January 03, 2014, 11:37:00 AM » |

0

|

Jim, Could the flanges could be recessed on a slight angle to eliminate the S bend & stop the link. Dave.  |

|

|

|

|

Logged

Logged

|

Dave

0417 270 315

|

|

|

|

fcwrangler

|

|

« Reply #137 on: January 03, 2014, 12:43:48 PM » |

0

|

Dave, one of the idea's, also as Haydn said recess them a bit (lot of work). At this stage time isn't an issue so I can play around and see what will be the neatest and easiest way to go.

Jim

|

|

|

|

|

Logged

Logged

|

on the seventh day: God Made Holden

|

|

|

|

hsv-001

|

|

« Reply #138 on: January 03, 2014, 01:35:26 PM » |

0

|

Maybe an old set of those steel cup like things you know the front end mount retaining plates that sit inside your front end rubbers .Trimmed back and then welded into the pillars and doors to give room for the hose to move and the ones in the doors could also give direction so the hose won't hit on window tracks . Butt welded into a hole pre-drilled with the correct hole saw and finished with body filler should look OK . Cheers Haydn

|

|

|

|

|

Logged

Logged

|

|

|

|

|

NES304

|

|

« Reply #139 on: January 03, 2014, 03:20:53 PM » |

0

|

I did this to my front door and has worked every time. Although I would have liked to use the braided one. Had to butcher a bit to go up. Will clean it up later so that sharp metal won't cut through  |

|

|

|

|

Logged

Logged

|

|

|

|

|