|

ocker

|

|

« on: August 03, 2007, 02:08:59 PM » |

0

|

Hi to all. The roller rocker conversion was a success.

A bit of trial and error, but the yella terra 1.65 holden v8 rockers are on

the old grey head,man what a difference! I have sent installation description

and illustrations to the admin people,hopefuly they can convert it to a more user-friendly format for all to see.

Cheers, Ocka

|

|

|

|

|

Logged

Logged

|

|

|

|

|

craiga

Guest

|

|

« Reply #1 on: August 03, 2007, 02:36:53 PM » |

0

|

Wow!! Great job. I'm looking forward to seeing the description/pictures.

I wonder if this has ever been done before?? Lots of guys were hotting these up over the years, but i can't remember anyone ever talking about putting roller rockers on them. Did you cry when you had to cover this amazing feat with a rocker cover?

Roller rockers on a grey. Will it rev past 4000rpm now ;-)

Tell us more. What is done to the rest of the engine/head?

I don't remember the original post but very impressed and interested.

Cheers,

Craig.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

RET

|

|

« Reply #2 on: August 03, 2007, 03:04:11 PM » |

0

|

Who've you sent it to? Nothing's turned up in the admin@fefcholden.org.au inbox. I'll be only too happy to see what I can do with it once it arrives. Sounds very interesting indeed. cheers RET |

|

|

|

|

Logged

Logged

|

|

|

|

|

ocker

|

|

« Reply #3 on: August 03, 2007, 04:08:29 PM » |

0

|

Hi and thanks for the response. It was sent to committee@qld.fefcholden.org.aubut i am thinking this is wrong? I will send it again to admin,hopefully it will make some sort of sense. Please forgive the quality, i am still new to these compooter thingys... Cheers,Ocker |

|

|

|

|

Logged

Logged

|

|

|

|

|

RET

|

|

« Reply #4 on: September 21, 2007, 11:26:41 PM » |

0

|

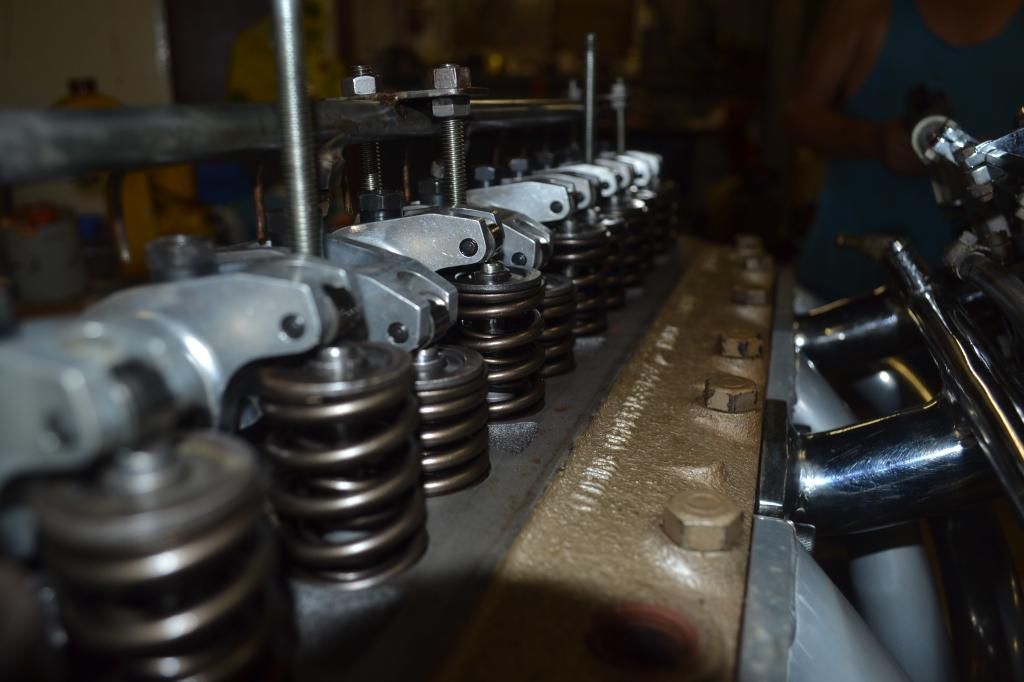

Bob sent me the pics and the story of his conversion about two weeks after his last message, and I promised to tidy it up for him and post it. So apologies to Ocker and everyone interested in the story for being such a slacker in getting this up on the forum...

I own a well worked grey in an FC Holden and had to pull down the engine because the balancer came loose on the crank. While inspecting some minor wear on the valves and guides I thought, how do I cut down on the friction between the valves and rockers? I used a Y/T rocker (1.65:1) and a stud and placed it on the head. My wife swears she could hear gears turning. I then drew a plan of a mounting plate that would carry the screw in rocker studs and would be held down by the head bolts and use the original rocker mount bolt holes. I then took this drawing to an engineering shop. Correct and accurate plans were drawn on the computer, transfered to a memory stick and then inserted into a water cutter. The 7/16 n.c. threads were cut in a milling machine. 3/8 n.c. studs can also be used. I happened to have a set from a 308 that are 7/16 studs that I used.  Photo 1. Mounting plate. Photo 1. Mounting plate.Next step, drill a hole in the block thru no 2 cam bearing. Drill thru the bearing and clean the burrs from the bearing. I used a 5/32 drill and tapped an 1/8 bsp thread at the top to replicate the oil supply at no 3 cam bearing. I then had a small groove machined in the no 2 journal of the cam to carry the oil to the fitting.  Photo 2. Oil fittings. Photo 2. Oil fittings.Next, this would be the ideal time to change the cam grind if required. Have the followers reground and have an engineering shop machine up a set of follower caps and get them hardened. This is needed as the push rod will be too short after cutting the cup head off and reshaping it to fit the roller rocker. Plus a shorter pushrod is desirable in any engine.   Photo 3 Cam follower and caps. Photo 3 Cam follower and caps.Next, fit the cylinder head with the mounting plate. (Some hand filing may be required to correctly align all bolt holes.) You will have to purchase new from the bolt shop ½ longer, and the two end bolts will have to be socket head bolts. I cut the push rods too and rounded off the ends. I used a thin cut-off wheel in a 4 angle grinder as it is easier and more accurate than a hacksaw.  Photo 4 Push rod and bolts. Photo 4 Push rod and bolts. |

|

|

|

« Last Edit: September 21, 2007, 11:33:35 PM by RET »

|

Logged

Logged

|

|

|

|

|

RET

|

|

« Reply #5 on: September 21, 2007, 11:32:54 PM » |

0

|

Next... Fit cam, followers, caps, pushrods, rockers and adjusters, then set the tappets. Crank the engine thru a few revolutions and check that the valves have not run out of travel. e.g. Springs bound or valve cap has crashed into the guide. This will depend on the lobe lift of your cam.   Photo no. 5 Push rods and rockers. Photo no. 5 Push rods and rockers.I used a length of 12mm hydraulic tube mounted above the rockers on 5/16 rod with mounting plates (as per photo), drilled and silver soldered two brass fittings, 1/8 male bsp x 3/16 flare pipe. I then drilled 12 holes in the tube above where the rockers sit and silver soldered capillary tube into these holes. This will squirt oil at the oil hole in the rockers, which I countersunk to assist the oil to lead into the hole. This is to lubricate the pushrod ball to rocker, the needle rollers and the roller tip. I then made two 3/16 tube from the cam bearings fittings (previously installed) to the oil rail over the rockers. I tapped and fitted 1/8 bsp plugs to the end of the rail.  Photo 6 Oil rail and fittings. Photo 6 Oil rail and fittings.I dont know what H/P gain this mod will give because I've done other mods at the same time. But with a friction loss and an extra 42 thou of valve lift from 1.65:1 rockers there will have to be some! Next mod next year. Roller followers and cam with sequential fuel injection with 65mm throttle body and computer control spark timing. I can supply a mounting plate with threads 3/8 or 7/16 for $360.00 plus freight. Any handy rev head should be able to handle this job. Regards Bob Jamieson. a/h phone no 0740566303 |

|

|

|

|

Logged

Logged

|

|

|

|

|

RET

|

|

« Reply #6 on: September 21, 2007, 11:39:48 PM » |

0

|

There has been a problem. I wrote this information before I test ran the engine. The grey motor push rods that were ball ended to match the roller rocker cup didnt work out. I had to machine down a grey push rod, cut off 15mm of red motor pushrod and press the grey rod into it . I then silver soldered it together, as in photo. I also had a new tappet cover made higher to cover the oil rail.   I now have the engine running and what a performance increase! Strong from idle to 6,000 rpm. I give it one hit in first gear and it went to 7,000 rpm. A dyno will be done after run in period to get an accurate reading and check exhaust reading. Then looking forward to some cruising and fuel using.  From my research I can't find anything to suggest anyone else has ever done this mod. Am I the first? Has anyone heard of anybody else that has done it? Would like to know. Regards, Bob Jamieson. |

|

|

|

|

Logged

Logged

|

|

|

|

zulu

nsw-club

Guru

Offline Offline

Model: FE and FC

Posts: 1867

Old Boonah Ambo

|

|

« Reply #7 on: September 22, 2007, 12:27:27 AM » |

0

|

Congratulations are in order Bob, looks like your perseverance has paid off big time. It's great to see someone having a go at improving a grey.

Good luck with it, look forward to hearing the results of your future plans for the engine.

Cheers, Gary

PS Lets see some pics of the rest of the car too

|

|

|

|

|

Logged

Logged

|

|

|

|

|

FC0058

|

|

« Reply #8 on: September 22, 2007, 09:37:03 AM » |

0

|

Hi Bob

Thanks for share your modification with us job well done.

Cheers Jim

|

|

|

|

|

Logged

Logged

|

Forgiveness is easier than permission.

|

|

|

customFC

nsw-club

Guru

Offline Offline

Model: FC

Posts: 5903

Ask me about microwaving cats for fun or profit.

|

|

« Reply #9 on: September 22, 2007, 04:21:31 PM » |

0

|

Hey Bob.

That is a fantastic conversion, some cleaver engineering there.

Love the fact that you took detailed pics along the way and shared them with us......thank you.

Like Gary said, let's see the rest of the car!

Of equal interest is that grill in the first shot.

If I am not mistaken, that is the front clip from Lionel Pitts, custom FX Holden from the past.

Would love to hear the story behind that clip and more pics.

Regards

Alex

|

|

|

|

|

Logged

Logged

|

|

|

|

weddo

tas-club

Senior Member

Offline Offline

Model: FC

Posts: 726

HIS, HER's & OUR's

|

|

« Reply #10 on: September 24, 2007, 12:57:37 PM » |

0

|

Congratulations Bob, What a great little bit of engineering!!  I love seeing someone doing smart things with a grey motor. Love the tripple SU's. What size needles do you run in them? I am still trying to find the ideal size for my hot grey motor. regards Weddo |

|

|

|

|

Logged

Logged

|

|

|

|

|

ocker

|

|

« Reply #11 on: September 24, 2007, 01:04:27 PM » |

0

|

Hi to all and a big thank you to RET for doing a great job organizing the information so everyone

can share the fun.

The car is still going great,other than a tappet re-set it is motoring on mightily! No dyno yet, but that will happen soon i hope.

I will post some pics of the car too, as it is not a bad looking old girl...(poverty pack version!)

The wife helped me restore it about 10 years ago.

As for the interesting front clip in the first pic... it was placed in the pic so as to try and arouse some interest, and to help me research the origins of this car. I came upon the complete car in a garage clean-out,although it is in a sad state at the moment.It is however redeemable, can anyone help with info and hopefully some pics?

Thanks for the kind words and encouragement,more soon.

Cheers, Bob Jamo(ocker)

|

|

|

|

|

Logged

Logged

|

|

|

|

|

|

colt

act-club

Senior Member

Offline Offline

Posts: 869

I love YaBB 1G - SP1!

|

|

« Reply #13 on: September 24, 2007, 09:12:31 PM » |

0

|

Bob, there is a car in the Appendix J circuit with roller rockers. He went another direction, basically scratchbuilt. I like the way you have done your set. A bit of fiddling, but like you say,anyone with some basic skills should be able to put a set together.

Colin.

|

|

|

|

|

Logged

Logged

|

colt

|

|

|

|

Ed

|

|

« Reply #14 on: September 27, 2007, 09:15:13 AM » |

0

|

that's brilliant!

very clever engineering.

Cheers

Ed

|

|

|

|

|

Logged

Logged

|

in the shed

|

|

|

|

Craig FB

|

|

« Reply #15 on: May 10, 2008, 11:23:40 AM » |

0

|

Hi great work how is this going

|

|

|

|

|

Logged

Logged

|

Hair like engine Fast going Grey

|

|

|

|

sexyfc

|

|

« Reply #16 on: May 10, 2008, 01:26:08 PM » |

0

|

hey, good stuff. Thanks for sharing the info!!  |

|

|

|

|

Logged

Logged

|

Project started 16/01/08.

|

|

|

JSM

Junior Member

Offline Offline

Posts: 41

I love YaBB 1G - SP1!

|

|

« Reply #17 on: June 05, 2008, 10:16:47 PM » |

0

|

How'd she end up going on the dyno? Worked out how much of a performance increase you managed to get yet? Great work btw!

Cheers

|

|

|

|

|

Logged

Logged

|

On a Mission to fix up my Ute, Five years down so far... hopefully this'll be the last before i can drive her!!!

|

|

|

|

ocker

|

|

« Reply #18 on: February 12, 2015, 10:07:06 PM » |

0

|

Hello all Been a while have been super busy. The FC has been going fantastic since the roller rockers were fitted, including a trip to Brisbane and back to Cairns, after 30,000 miles and plenty of rpm by Me and my Son, the old girl developed a compression leak into the cooling system. the head was removed, and had to be machined flat again. while I was down this far my son conned me into fitting the roller cam and followers that had been in the cupboard for years. the cam chosen is a Tighe billet camshaft with a 35/75 overlap and solid big block ford followers. the cam had another .30 thou lift over the previous solid cam and was only a 30/70. we found that the exhaust valves were going to hit the pistons, this meant that a full engine pull down to get the piston out and to get them machined for the extra lift. while the engine was ot an inspection of the lower end reveled that the bearing where still like new from the box(even after many visits to 6500 and beyond) a valve spring travel test found that the springs would bind and was found that valve seat pressure would not be sufficient for a roller cam. A call to my mate Pete in Brisbane who has earned his living building race engines found the right springs( from a Porsche inner and outers) would give a valve seat pressure of 95 pound. I also purchased some 8mm chrome molly push rods, I then had to machine out my adapter plate to fit the new push rods. The engine is assembled and in the car now, a aluminum radiator is being fitted and the stock fan will be deleted, to make up for this two 10" thermo electric fans will be fitted, the front opening had to be opened up to accept the new width of the radiator ( now it won't sound like a Cessna taking off) and will give a bit more horse power in the upper rev range. this time I will get a dyno run done as last time it was running so sweet!      It now has .515 thou of valve lift. this should make it breath  This is my initial build of an electronic dizy for the grey. It is a red motor housing, grey motor shaft and ford electronics and rotor cap(hybrid)! I hope one day to build a grey with electronic sequential fuel injection    The guru in Brisbane estimates about an 8hp gain (what a lot of work for only a few horse power!!!) |

|

|

|

|

Logged

Logged

|

|

|

|

Professor Grey

Junior Member

Offline Offline

Model: FC

Posts: 98

|

|

« Reply #19 on: February 13, 2015, 09:29:32 AM » |

0

|

G'day Ocker,

Please excuse my ignorance, but I haven't seen those doodads connecting the cam followers before.

I mean the ones behind the sideplate.

Can you (or anyone else) tell me what they are for?

Cheers,

Prof.

|

|

|

|

|

Logged

Logged

|

You don't get this old by accident.

|

|

|

|