|

Harv

|

|

« on: September 01, 2014, 06:17:25 PM » |

0

|

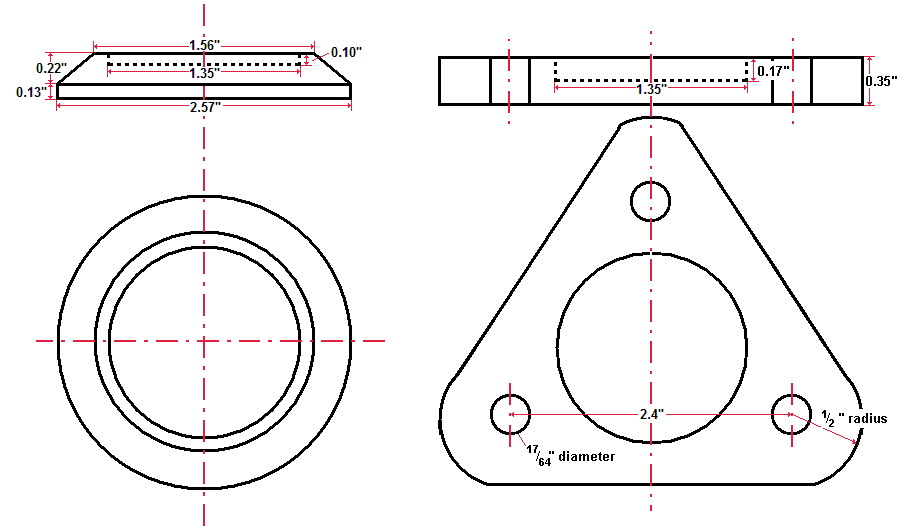

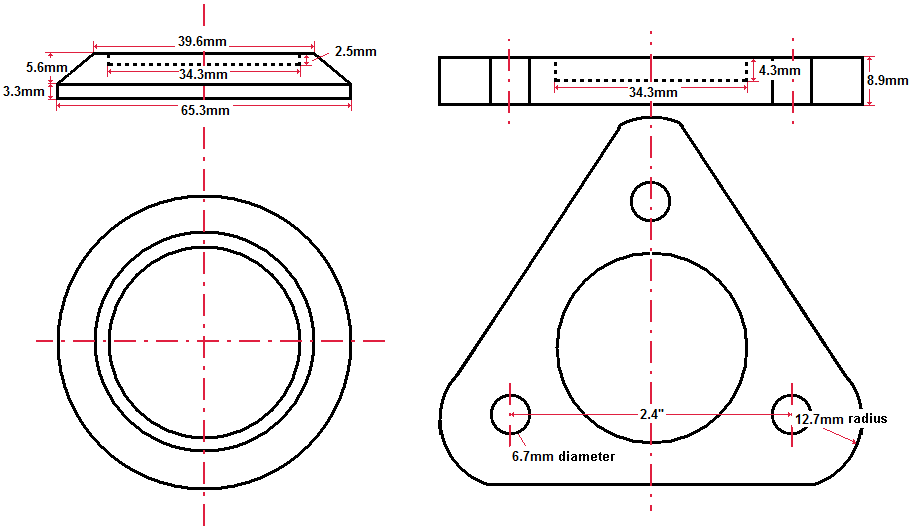

Ladies and Gents, I need to make a relief valve for the Type 65 Norman supercharger in my recent posts. To do this, I need two aluminium pieces machined up - a triangular one, and a disc:  Whilst I can cut plate, I can't turn/mill the 1.35" "indents" in each piece (the indents are used to locate a grey motor valve spring). Drilling is not an option as the point of the drill bit would push too far into the ally. I'm looking for someone with a lathe/mill who is willing to make these up from aluminium. Happy to pay for both time and materials. For now I only need one, but would be willing to purchase up to eight (eight discs, eight triangles). I can probably get this done through one of the local machine shops, but would prefer to keep it on the forum if I can. Cheers, Harv |

|

|

|

|

Logged

Logged

|

|

|

|

|

FCRB26

|

|

« Reply #1 on: September 01, 2014, 07:00:49 PM » |

0

|

ill see what thickness ally i have. (after i do the conversion) Bloody old timers with their imperial measurements  |

|

|

|

|

Logged

Logged

|

|

|

|

|

GM

|

|

« Reply #2 on: September 01, 2014, 08:39:39 PM » |

0

|

Bit cheeky Pete, where I served my time all the machines were in imperial. Thankfully we got digital readouts on most and I didn't have to convert. Lot's of the measurements Harv has given you don't add to any standard imperial or metric?  ? |

|

|

|

|

Logged

Logged

|

Upon the hill there stood a cow.

It must have moved, It's not there now.

|

|

|

|

FCRB26

|

|

« Reply #3 on: September 02, 2014, 06:10:48 AM » |

0

|

Sorry i should explain i have a on going joke with all the old fella,s at lake maquarie model steam society they all bring there imperial train drawing for me to convert over to metric for them so we give a bit of banter over it. I use this convertor as you can type in decimals or fractions and still get an answer eg 17/64 type it in exactlly like that and it gives an answer. http://convert.french-property.co.uk/ It must work as i cut these for a lady she is building 2 14ft live steam garrets for australian model engineer magazine. lots and lots of converting.  |

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #4 on: September 02, 2014, 07:07:15 AM » |

0

|

C'mon Pete, I ain't that old. I grew up metric, but old Holden always feels imperial. I converted it to metric below... made me feel a little queasy   It would need to be about 9mm ally plate. At a pinch, steel would do. Cheers, Harv |

|

|

|

|

Logged

Logged

|

|

|

|

|

FCRB26

|

|

« Reply #5 on: September 02, 2014, 11:40:18 AM » |

0

|

I have 12mm sheet in stock

I will use the CNC router to do the rebates so there isnt an actual hole thru the centre?

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #6 on: September 02, 2014, 03:02:21 PM » |

0

|

12mm sheet will be fine Pete - too thick is OK, too thin is not. Please do use the router - there is no hole through the centre, just a rebate (one in each piece) to sit the spring in. Circular piece is a rebate 34.3mm diameter and 2.5mm deep, triangular piece is a rebate 34.3mm diameter and 4.3mm deep. They are sized to use a grey motor valve spring. Let me know how much I will owe you Pete - if you are going to the trouble of whacking these up on CNC, I'll aim for a dozen of each piece please. Would not be suprised if our mate with the red EH wants one  Cheers, and thanks, Andrew |

|

|

|

|

Logged

Logged

|

|

|

|

|

GM

|

|

« Reply #7 on: September 02, 2014, 04:11:01 PM » |

0

|

Just shit stirring

|

|

|

|

|

Logged

Logged

|

Upon the hill there stood a cow.

It must have moved, It's not there now.

|

|

|

|

FCRB26

|

|

« Reply #8 on: September 02, 2014, 06:37:03 PM » |

0

|

Just shit stirring

Me too  Ill do 1 of each to get us out of trouble i finished another manifold for dan and i have been dangling like a carrot 2 175cd side draughts or a 48mm dellorto trying to convince hime to get rid of the gas.. Pete |

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #9 on: September 02, 2014, 06:49:10 PM » |

0

|

Thanks Pete.

Give me a yell when they are near-ready and I'll transfer some cash and confirm the address.

No rip-tear-rush, still on the road for work.

Cheers,

Andrew

|

|

|

|

|

Logged

Logged

|

|

|

|

|

john253a

|

|

« Reply #10 on: September 03, 2014, 05:49:52 PM » |

0

|

You know what funny about this

The shop I work in and build tankers still uses whitworth bolt, as they have for the last 50years,

Asked why, and was told they worked for last 50years so why change

|

|

|

|

|

Logged

Logged

|

Good + Fast = Not Cheap

Cheap + Fast = Not Good

Good + Cheap = Not Fast

|

|

|

|

Harv

|

|

« Reply #11 on: September 03, 2014, 06:07:43 PM » |

0

|

"Shoot, them Whitworth bolts is a pain, tell you what. Them ain't metric, they ain't inches."  - Mater, Cars 2. |

|

|

|

|

Logged

Logged

|

|

|

|

|

GM

|

|

« Reply #12 on: September 03, 2014, 08:02:07 PM » |

0

|

Some trivia for you, BSW thread is 55 degree, UNC is 60. and they only change pitch at 1/2 inch diameter. If anyone would really care..............

|

|

|

|

|

Logged

Logged

|

Upon the hill there stood a cow.

It must have moved, It's not there now.

|

|

|

|