|

Phantom

|

|

« on: April 30, 2007, 02:00:37 AM » |

0

|

G'day all, HELP, i have put a two speed wiper motor in recently(thanks ken) and have spent a lot of frustrating hours trying to get the wiper arms to move at the same time , whatever position i put the driver arms on the motor one arm always goes first then the other arm follows at a different time completely out of sync, what am i doing wrong? The arms are pretty sloppy i need to get the nylon inserts in the wiper arms, but it didnt do it before i changed motors and i thought i have put it back together the same way as it came off, any ideas? Cheers Rusty  |

|

|

|

« Last Edit: April 30, 2007, 02:02:12 AM by phantom »

|

Logged

Logged

|

Bogans rule

|

|

|

Just40

qld-club

Senior Member

Offline Offline

Model: FE

Posts: 374

I cant fix my brakes, so I made my horn LOUDER

|

|

« Reply #1 on: April 30, 2007, 04:57:48 AM » |

0

|

arms the wrong way around.  |

|

|

|

« Last Edit: April 30, 2007, 05:03:38 AM by just40 »

|

Logged

Logged

|

|

|

|

|

Phantom

|

|

« Reply #2 on: April 30, 2007, 05:21:23 AM » |

0

|

AHA, Thanks ever so much

Cheers a very very happy Rusty

|

|

|

|

|

Logged

Logged

|

Bogans rule

|

|

|

|

mcl1959

|

|

« Reply #3 on: April 30, 2007, 09:42:14 AM » |

0

|

The brackets are on 180 degrees out of phase or upside down, the arms should sit higher up which will make them react faster on start up

Ken

|

|

|

|

|

Logged

Logged

|

|

|

|

bent8-58

Junior Member

Offline Offline

Posts: 95

The older it gets-the slower it was!

|

|

« Reply #4 on: May 02, 2007, 07:37:24 AM » |

0

|

Gaday! It might sound stupid but I found that if the motor isnt in the right place & the axle isnt exactly in the centre of the car( or arms) it also affects how they "behave!" Daz.  |

|

|

|

|

Logged

Logged

|

I LOVE CATS.....BUT I CANT EAT A WHOLE ONE BY MYSELF.

|

|

|

thephantom

Newbie

Offline Offline

Posts: 1

I love YaBB 1G - SP1!

|

|

« Reply #5 on: May 02, 2007, 08:47:34 AM » |

0

|

Nah just dumbarse me, got the wiper arms on the wrong driver arms, typical me rush in head down and bum up i have to take more time when doing things thats all

Cheers Rusty

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Ed

|

|

« Reply #6 on: May 11, 2007, 04:03:44 AM » |

0

|

Interesting...

im a dumbarse too. mine are on the wrong way around.

i was getting used to the un-co wiper set up too.

Cheers

Ed

|

|

|

|

|

Logged

Logged

|

in the shed

|

|

|

|

RET

|

|

« Reply #7 on: May 11, 2007, 05:03:25 AM » |

0

|

i was getting used to the un-co wiper set up too. There's a saying in software development: "any sufficiently advanced bug is indistinguishable from a feature"  |

|

|

|

|

Logged

Logged

|

|

|

|

|

NES304

|

|

« Reply #8 on: May 13, 2007, 09:38:18 AM » |

0

|

I'm actually just about to install my wipers too. I have an EK motor and a set of FC arms. Can I use these to attach to the back of the wiper motor? It looks like I need a little bracket to attach arms. Pointers?

|

|

|

|

|

Logged

Logged

|

|

|

|

|

mcl1959

|

|

« Reply #9 on: May 14, 2007, 04:17:42 AM » |

0

|

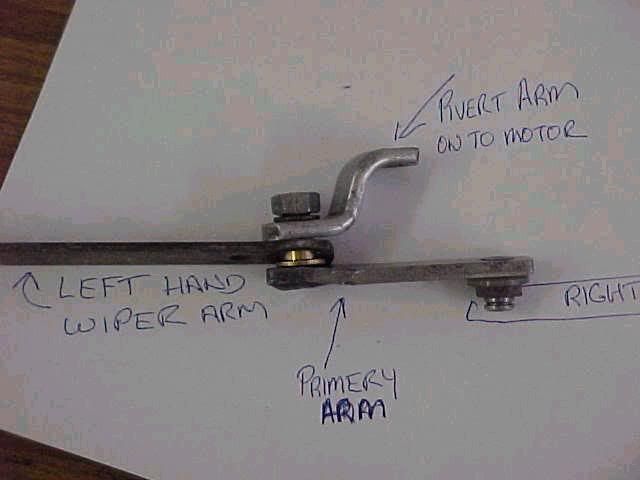

Nes you need the brackets shown in the first and second photos - these are the original EK parts and your FC wiper arms will connect to these.

Ken

|

|

|

|

|

Logged

Logged

|

|

|

|

customFC

nsw-club

Guru

Offline Offline

Model: FC

Posts: 5904

Ask me about microwaving cats for fun or profit.

|

|

« Reply #10 on: May 14, 2007, 10:43:55 AM » |

0

|

Anyone have a spare spring clip that holds the right arm on? Mine is broken and held in place with a cabletie.

PLMK.

Then I might check my instalation....I suspect it may be wrong!!

Regards

Alex

|

|

|

|

|

Logged

Logged

|

|

|

|

|

NES304

|

|

« Reply #11 on: May 16, 2007, 07:56:53 AM » |

0

|

Nes you need the brackets shown in the first and second photos - these are the original EK parts and your FC wiper arms will connect to these.

Ken Cheers Ken Any one have any? |

|

|

|

|

Logged

Logged

|

|

|

|

surferboy

wa-club

Guru

Offline Offline

Model: FE and FC

Posts: 1338

10,000 POINTS !

|

|

« Reply #12 on: January 01, 2010, 07:18:45 PM » |

0

|

surferboy is about to attempt mechanical stuff get ready for the questions I'm pulling the EK wiper motor off Cathys FE and fitting them to my FC wagon I got as far as removing the spring clip on the primary/right wiper arm pivot How do i remove the nut off the primary/left wiper arm pivot. The nut is around on the blindside and I dont have any room to fit a spanner then I have to figure how to remove the unit from the firewall. It has some screw and nut (?) arrangement buried under insulation and that cardboard interior lining stuff  Will unscrewing the motor off the firewall first, give me better access to that pivot nut Ta    please hurry with an answer...my weekend is dissapearing quickly |

|

|

|

|

Logged

Logged

|

cruisin's great with a 58

|

|

|

surferboy

wa-club

Guru

Offline Offline

Model: FE and FC

Posts: 1338

10,000 POINTS !

|

|

« Reply #13 on: January 01, 2010, 08:12:27 PM » |

0

|

The nut is A ...its tucked in nice and tight near the firewall(?) and i cant get my big fat hands in there, especially with the spaghetti bowl of wiring under the dash ! The wiper unit seems to be screwed in B . I thought it would be a nut and bolt fittment (it is on the spare in the shed). I want to have wipers for the trip to the Nats so I was going to fit the spare motor in the wagon and just swap the crank parts over (cos i cant find any crank parts anywhere) but this silly nut problem is bugging me  I have a VERY short impatience level ! This is why i pay mechanics $90/Hr to do things    and I've got my hands DIRTY  |

|

|

|

|

Logged

Logged

|

cruisin's great with a 58

|

|

|

surferboy

wa-club

Guru

Offline Offline

Model: FE and FC

Posts: 1338

10,000 POINTS !

|

|

« Reply #14 on: January 01, 2010, 08:54:49 PM » |

0

|

WHOOPS   I managed to undo the B screw on the right hand side and then I managed to mangle the head of the B screw on the left and then I remembered why I pay mechanics $90/Hr to do these things for me I'm packing my screwdriver away now One days work and I managed to 1.remove one clip, 2.remove one small screw, 3. bugger up one small screw    |

|

|

|

|

Logged

Logged

|

cruisin's great with a 58

|

|

|

FCV08

Senior Member

Offline Offline

Model: FC

Posts: 692

FE FC Club of QLD

|

|

« Reply #15 on: January 01, 2010, 09:04:05 PM » |

0

|

Surferboy Good to see you having a crack at it. Can you get access with an 4" angle grinder? If so grind the head of the screw off without damaging the wiper linkages   . The wiper mount I have is a nut and bolt setup with the nut on the inner side. It is actually mounted on rubber mounting washers. Keep up the good work and let us know how you go. Cheers Craig |

|

|

|

|

Logged

Logged

|

|

|

|

|

mcl1959

|

|

« Reply #16 on: January 01, 2010, 09:44:38 PM » |

0

|

OK - the spring clip is made of unobtanium - It can be replaced by the appropriate sized circlip available from every local milkbar and it will work fine.

Surferboy - use a 7/16 open ended spanner to undo the nut by feel - It should come undone easily. BE VERY CAREFUL when doing it up not to cross thread it as it is easily done because of the flats on the sides.

The motor cannot be removed from the plate until the plate is removed from the firewall so the 2 small screws must be undone or cut off as suggested. This is probably one of the worst design features in the EK.

You could try a small chisel to try to loosen them but it just may come down to the grinder.

Ken

|

|

|

|

|

Logged

Logged

|

|

|

|

|

DN2168

|

|

« Reply #17 on: January 01, 2010, 10:01:45 PM » |

0

|

Surferboy, I feel your pain re the screws. Mine were bolts but it took an hour of trying to get a socket to fit on the drivers side bolt head because of the angle & lack of room. Finally dawned on me to use an open ended spanner, even that was fun.

When I put the setup in my FC I am going to use allen headed bolts. Hoping these will be easier to work with.

Dean.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Paul In Ireland

|

|

« Reply #18 on: January 02, 2010, 01:44:28 AM » |

0

|

And here I was thinking my spastic wiper arms were Kens fault  (just kidding Ken) so I think I will have a peek this evening and I reckon I have the same incorrect setup.  |

|

|

|

|

Logged

Logged

|

The International FE FC Fleet of Ireland

Education is where you read the fine print. Experience is what you get when you don't.

|

|

|

Geoff_K

nsw-club

Senior Member

Offline Offline

Posts: 309

The 2 BAY s

|

|

« Reply #19 on: January 02, 2010, 02:50:23 PM » |

0

|

Many years ago I had the same problem with those bolts.

I made up a bracket that fitted between the bolt heads (on the inside, and bent to miss the moving arm) and welded the bracket to the bolt heads.

Made the task a breeze, as it did not fall out or allow the bolts to turn, when you were around the other side in the engine compartment.

Geoff

|

|

|

|

|

Logged

Logged

|

|

|

|

|