|

Harv

|

|

« Reply #240 on: September 02, 2014, 09:34:35 PM » |

0

|

The photo below shows Rilstone working on the Zephyr at Port Wakefield in October 1959.  Rilstone fitted the Zephyr Special with the newer (and larger) 2,553cc Mk2 Zephyr engine with a Raymond Mays head that he got from Charlie Dean at Repco. The head had apparently been purchased by Repco for evaluation during the design of the Hoden Hi-Power head. Rilstone also made changes to the front suspension, adding an antiroll bar and lowered the top wishbone pivot point, thus lowering the roll center of the car. Shock absorbers were moved outboard of the coil springs. PBR assisted in the setup of dual leading shoe brakes based on Vanguard components and fitted with twin boosters. Over time Rilstone increased the reliability of the car, getting to the point where he wouldn’t even wash it, in case he jinxed it. In 1959 Rilstone took second place in the Zephyr at the CAMS Gold Star race at Port Wakefield. In the same year he piloted the Zephyr Special in the Westernport Cup at Phillip Island gaining 5th place. In December of that year he recorded 124mph over the Flying Eight Mile at the Weapons Research Establishment Institute Sprints in South Australia. Rilstone campaigned the Zephyr Special through several years of the Australian Drivers Championship series. This was a CAMS-sanctioned Australian motor racing title for drivers of Formula Libre cars, contested over a number of rounds. Points were awarded for various placings in each round, with the overall highest number of points at the end of the series being awarded the CAMS Gold Star. • 1957 was a nine-race series. Rilstone placed fourth in the October Wakefield Trophy race at Port Wakefield circuit, earning him equal 17th position (of 22 positions) in the Australian Drivers’ Championship. • 1958 was also a nine-race series. Rilstone placed third in the April South Australian Trophy Race at Port Wakefield circuit, earning him equal 11th position (of 15 positions) in the Australian Drivers’ Championship. • 1960 was also a seven-race series. Rilstone placed third in the October Advertiser Trophy Race at Mallala circuit, earning him equal 10th position (of 18 positions) in the Australian Drivers’ Championship. The image below, taken from With Casual Efficiency, shows the Zephyr (at far left) at Port Wakefield in Easter 1957.  The image below shows Rilstone in the #8 Zephyr at Port Wakefield in 1960.  Rilstone entered the Zephyr Special in the 1961 Australian Grand Prix at Mallala, which was a round of that year’s Australian Drivers Championship. The dark green Zephyr can be seen in the left background of the photo below.  The Zephyr started on the third row of the grid, but did not finish the race. The Zephyr Special was the first of seven cars to retire from the seventeen car field, completing thirty-three of fifty laps (105 miles). Whilst Rilstone returned to the Australian Grand Prix in 1964 (in a Ford powered Elfin FJ), the 1961 race represented the last time one of Eldred’s machines competed in the Australian Grand Prix. Eldred’s vehicles thus entered the Grand Prix a total of ten times: • the Double Eight in 1950 (DNF) and 1951 (DNF), and a non-start (DNS) in 1957 under Carboni, • the Maserati 6C in 1951 (DNF, albeit under Murray’s ownership), in 1952 (DNF), and then in 1953 (15th position, under McKinnon’s ownership), • The Triumph TR2 in 1954 (4th position), and probably in 1955 under Brown (though did not get past qualification), and • The Zephyr Special in 1955 (8th position), and in 1961 (DNF, under Rilstone). |

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #241 on: September 02, 2014, 09:35:12 PM » |

0

|

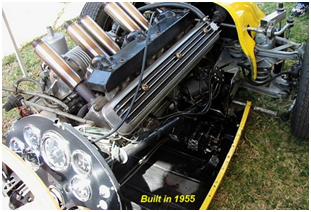

Rilstone also entered the Western Australia State Championship in October 1961, competing in Event 5 the fifteen-lap Racing Car Championship. The Zephyr retired after ten laps. He also competed in the Advertiser Trophy at Mallala in October 1962. After qualifying fourth, Rilstone retired having completed twelve of the twenty-five laps. The image below shows Rilstone in the #8 Zephyr at Mallala in 1962.  Rilstone ran the car competitively right through to 1963 before selling it to Robin Reade. Robin had the vehicle until 1964, when it passed to Don McArthur, and then in 1968 to two young gentlemen who utilized the vehicle as a beach buggy. The car slowly lost shape, with the friendship of the two gentlemen equally declining. They finally decided to split the car between them, engaging a local garage to break the car behind the engine. It then sat in the mechanic’s shed for some years as the workshop had not been paid for the work. The vehicle was tracked down and rescued in 1973 by Ken Messenger. Messenger purchased all the pieces and brought them together before running the car in historic racing. The Zephyr would melt pistons at the Sporting Car club of South Australia’s Historic Races in April 1975. Messenger then sold the vehicle in 1978 to Peter De Mack in Adelaide, who completely rebuilt the car. The #6 Zephyr is shown in the image below in 1983 being driven by Kevin Shearer at the Victor Harbour Quarter Mile Sprints (Alf Blight was at the wheel of Eldred’s Maserati for the same event).  The Zephyr Special was purchased from Peter by Graeme and Robyn Snape of Gundagai NSW in 1983. Graeme is shown driving the (now green and #6) Zephyr in the image below.   The current engine is bored 0.040” over, balanced and has conrods from a Toyota twin-cam engine running on the standard Zephyr crankshaft. Mahle pistons are fitted that Peter de Mack had made during his ownership. Except for the original drop gear, it’s been some time since the gears in the gearbox resembled anything that left the ZF factory. First gear in the Zephyr Special is actually the same ratio as the original third and the box lost its reverse years ago. The car’s Achilles heel has always been the transmission, although that was sorted out once the Snapes found the right steel to make the input and output shafts. The car has thrown one rod in the Snape’s ownership due to low oil pressure. The car is very hard on clutches being very high-geared with 90mph in first gear, 130mph in second and more than 150mph in top. It will see close to 160mph down the straight at Eastern Creek and Phillip Island, pulling 6,300rpm. In a straight line it is a very stable car, but it hates fast, sweeping corners due to its short wheelbase. When the Snapes were considering taking the vehicle overseas to the Goodwood meeting in 2000, the Zephyr Special was deemed to be a protected object under the Protection of Movable Cultural Heritage Act 1986, requiring a permit from the Commonwealth Department of Communications, Information Technology and the Arts for its temporary stay overseas. |

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #242 on: September 02, 2014, 09:35:53 PM » |

0

|

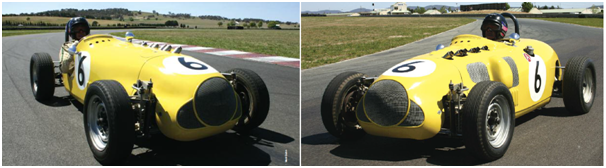

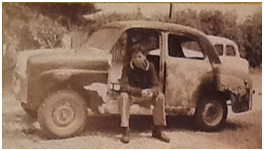

The photos below are from the Snape’s ownership of the Zephyr. The photos below in the #6 guise I have taken from Patrick’s article, whilst those in #5 guise from Ted’s.              9. Odds and Ends – The Trials Vehicles 9. Odds and Ends – The Trials VehiclesIn the same year that Eldred sold the Zephyr Special, he also competed in a round Australia trial (the 1956 Mobilgas Trial). Eldred drove car #54, a Ford Anglia 100E. The navigator was racing identity David Harvey. Unfortunately, the Norman/Harvey entry did not finish. This was a grueling race, with only two of the thirteen Fords entering finishing (Holden did little better with four of thirteen entrants finishing). Whilst Eldred did not compete in the earlier 1953, 1954 and 1955 Redex trials (nor the later 1956, 1957, 1958, 1964 Ampol trials nor the 1958 Mobilgas trial), he does get a mention in the advertisement from Adelaide’s Advertiser (3rd of July 1954, se clipping below), which indicates Eldred used Redex. Note that the article but does not list him as a Redex trials entrant (it does however list “Possum” Kipling).  Some of Eldred’s race vehicles are a little harder to tie down than those noted above. • Soon after starting out, Eldred purchased an ex-Black and White Holden taxi. The taxi was suffering badly from big-end noise. Eldred announced they were entering it in the Advertiser 24 Hour Trial the next weekend. After shimming the bearings with cut-down Benson and Hedges tobacco tins, he won the trial. During trial racing Eldred was known to keep himself awake by butting cigarettes on the back of his hand. He once became annoyed by a car which would not move over, until it was rammed with vigour. • It is believed that a Ford Prefect used by Eldred in the 1956 Advertiser 1000 Mile Reliability Trial had some secret weapons: for short period power, a container mounted above the carburetor filled with nitromethane; windscreen wipers were put on the headlights, operated in conjunction with washers activated by the navigator from an upturned Holden fuel pump operated by foot; and tractor tread tyres. The weapons must have worked, as Eldred won. |

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #243 on: September 02, 2014, 09:37:19 PM » |

0

|

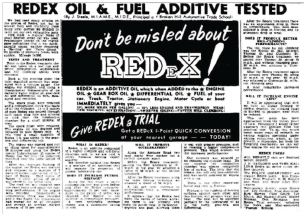

10. Post Racing – inventions and travelsAfter selling the Zephyr in 1956, Eldred abandoned racing to concentrate on inventing. He built a large astronomical telescope in the property’s tin shed, then a rotating observatory in the "plane paddock". The plane paddock had an old twin-engined bomber training aircraft that Eldred had brought back from one of his trips to Papua New Guinea. The Norman children would play in the aircraft, and later cut it up with an axe. Eldred’s sunny observatory, complete with opening roof, became a favourite for Nancy’s writing. A car gearbox was employed to rotate the truck chassis base (mounted to a twenty-tonne block of concrete) to compensate for the earth’s rotation. The telescope operated with both pneumatic and hydraulic components, and had no fewer than twenty electric motors. Scientists from the Weapons Research Establishment (the Commonwealth body engaged in defence research, ammunitions and explosives or weapons industries, based in Salisbury South Australia) would visit to see his home-made automatic telescope mirror-grinding machine complete a cycle, watching as it automatically applied paste, water, rotated, oscillated and separated, grinding mirrors to a tolerance of 0.000003”. Eldred’s 14” cassegrainian telescope (a reflecting telescope that has a paraboloidal primary mirror and a hyperboloidal secondary mirror) is shown in the image above right from Ray’s article, and was later sold to Clive Clisby.  An anecdote related to Eldred’s observatory, Eldred’s fear of spiders and some interesting inventing is related by Ray: “Steve Tillet once offered Eldred Norman a cigarette, handing him a tin which, when opened, revealed the arachnid. After letting out a scream, Eldred’s reaction was rage. Steve bolted out of the workshop and jumped into his Morris Minor, with Eldred in hot pursuit. A couple of times around the block and Eldred got alongside and pushed him into the gutter. He was about to pummel him when three police officers walked up... So real was Eldred’s fear of spiders that he went to great lengths to keep them out of the observatory. But then. If anything caught his attention there seemed no limit to the effort he would expend... A rail of aluminium was installed right around the base on the outside. It was insulated from the building, and located so that any visiting spider had to climb over it. Which was pretty tough, because it carried 2500 volts!” Many of Eldred’s prototypes, including a car tow-bar and a photographic device to capture burglars, never reached the production stage.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #244 on: September 02, 2014, 09:37:57 PM » |

0

|

With Nancy, he made a motoring trip in 1961 which took them through seventeen countries, including the Soviet Union, Poland, East Germany, Turkey, Iran and Pakistan. A sign of the times was ASIO’s interest in Communism. There is a one hundred-page file covering Commonwealth Police investigations into the Norman’s activities. ASIO intercepted the Norman’s mail and recorded telephone conversations leading up to their trip. A confidential memo dated April 1961 to Headquarters ASIO from the Regional Director South Australia, indicates that they have nothing known regarding Eldred, but Nancy's name was linked to others (details blacked out in the public report), was present at a public meeting of note, and had signed a petition organised by 'Overland' (a magazine who’s editor was an ex-member of the Communist Party). The Prime Minister Robert Menzies was well known for his anti-Communist views, and was kept informed by memo of the goings and comings of Eldred and Nancy. The trip was undertaken by shipping a 1961 Ford Falcon station wagon to Spain, complete with oversized 50-gallon fuel tank and camp bed in the back. They applied for passports to go to USSR and China in 1961. This request was vetted by ASIO, as part of their 'investigation' of the couple.

On returning from their trip Eldred and Nancy accepted an offer on the “plane paddock”. Whilst the labourers had to break up Eldred’s twenty-tonne concrete foundation, they had few tree stumps to clear… Eldred had done so some time previous with the gelignite noted below.

As Ray notes:

“No longer did the cleaning lady come in twice a week. She had worried Norman, desiring only to get her job done. For him it was a nuisance that she wished to hurry him, his daily reading of the newspaper before coming out to breakfast became a barrier to the smooth passage of her working day. Sometimes she would wash up the breakfast things before he rose, so that he would find the French polished table bare. One morning Eldred put an end to that problem. He got the hammer and put nails into the table to hold the table cloth on! It was not the only time he’d done something seemingly destructive around the house. A pop-up toaster insisted in troubling him, so he threw it on the floor, pumped on it and threw it out the window and over the hedge, where it lay for years.”

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #245 on: September 02, 2014, 09:38:32 PM » |

0

|

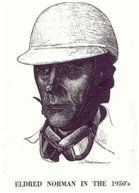

11. The Norman Superchargers – father and sons.Eldred is also renowned for his sliding vane supercharger manufacturing, which started in Adelaide and then continued after the family moved to Noosa in 1966. He is likely to have been influenced by a second-hand incomplete Arnott supercharger he purchased during his ownership of the Maserati. Eldred manufactured eight different superchargers (the Type 65, Type 70, Type 45, Type 75, Type 90, Type 110, Type 265 and Type 270), and adopted some truly innovated designs, including a supercharger clutch drive reminiscent of Mad Max’s car. Eldred’s superchargers ended up on a number of Mike and Bill’s vehicles, including an ex-PMG FE van and Bill’s supercharged MGTC, a winner at Lakeview Hill Climb in October 1965. Eldred’s reflections on supercharging were published in his book Supercharge! published in 1969. The image of Eldred below, taken from Supercharge! shows Eldred in his forties.  Eldred’s habit of road testing race vehicle continued, with his HD Holden utility acting as a test-mule for many of his superchargers. The HD had all drum brakes… interesting to handle given that when fitted with the Type 110 supercharger and Eldred’s own twin-needle 3” SU it could make 140mph. Only seven or eight of Eldreds’ 3” SUs were ever made between around 1969 and 1971. Note that the large SU on the Eclipse Special was not one of Eldred’s, rather it was from a specialty order from the UK. When fitted to a 186ci Holden red motor and Type 110 supercharger Eldred’s 3” SU would only lift around ¾ of its piston travel at 6,000rpm. Barrie Broomhall Motors had the first electric dyno in Queensland and one of the first in Australia. This was a measure of his business acumen and many noted engineers and companies hired his workshop to do development work on their projects. Among the more famous was Eldred Norman doing testing with supercharging. Eldred’s passion for sliding vane superchargers was taken up by his son Mike. Having been raised on a diet of supercharged vehicles, Mike Norman began building some superchargers from Eldred’s design in 1973-1975. Unfortunately, the original patterns and moulds for Eldred’s superchargers, stored under the house in Noosa, had been lost. From 1978 (through to 1984) Mike ran Offroad Automatics Pty Ltd at Magowar Road in Girraween, Sydney. Whilst the business was involved in fitting automatic transmissions to Range Rovers, Mike began to tinker with superchargers around 1983. Mike manufactured an improved version of the sliding vane design in Sydney the mid 1980’s, making six models (the 150, 200, 250, 300, 350 and 400). Around 1984 Mike was commissioned to supercharge the new four-door Range Rover owned by the managing director of Leyland Australia. This vehicle originally had 9.5:1 compression, and required new low compression pistons to go with the supercharger, manifolds and water injection. All up the project cost around $3500. Bear in mind that a new Range Rover in the UK was selling for around $18,000… This is roughly the equivalent (in today’s money) of buying a 2014 Holden Statesman and supercharging it for $13,000. Mike ceased automatic transmission operations in Girraween in 1985, moving to Noosa. The advent of newer more efficient supercharger type such as the Whipple and Eaton superchargers made for a declining market, and supercharger production was ceased.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #246 on: September 02, 2014, 09:39:09 PM » |

0

|

Whilst Eldred’s Norman-supercharged HD Holden utility is renowned, Eldred did not actively race superchargers of his own design, instead utilizing Roots, Arnott and Wade superchargers. However, both of Eldred’s sons ran cars with Norman superchargers onboard. Bill started racing at age seventeen in a Standard 10 (shown with Bill in the image below), fitted with a steel-cased Type 65 supercharger.  Bill won his first race at Mallala circuit in GT class. After serving a hard life on the track, the Standard 10 was later road-registered by Mike, though did not last too long. After limited success with the Standard 10, Bill then purchased (and later rolled) Steve Tillet's 1947 MGTC. Bill is pictured in the MGTC in the image below.  The standard 1250cc pushrod overhead valve XPAG engine had been fully balanced after fitting a 90-tonne crankshaft. The cylinder head was treated to porting and large valves, and a high overlap camshaft fitted. Bill fitted a steel-cased Type 65 Norman supercharger (seen in the image below), using flexible piping to connect it in suck-through mode. Boost pressure was operated at 10psi, with carburettion was via a 1½” SU.  To improve braking the MGTC was fitted with finned brake drums, air scoops on the brake backing plates and competition linings. Handling had been improved by the use of telescopic shock absorbers all round, 15” wheels with wide rims and radial tyres. To reduce weight, the body had a fiberglass tail and an aluminum bonnet, with a Vertex magneto removing the need for a battery. Running methanol, the MGTC’s power had increased from 55bhp to 85bhp (65 bhp at the rear wheels), giving a power-to-weight ratio 5½ times greater than our standard EK Holden. |

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #247 on: September 02, 2014, 09:39:42 PM » |

0

|

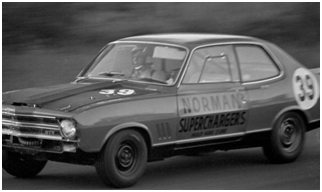

Bill also owned the front-engine supercharged Ford Cortina engined U2 around late 1968/early 1969. The vehicle had previously been owned by Tony Simmons, who crashed and very badly hurt himself at Oran Park circuit. Pictured below is Bill Norman’s LC GTR Torana. Bog stock standard, complete with 161ci (2600cc) straight-six and a Norman Type 110 supercharger.  The car had standard brakes, wheels, radials, suspension, exhaust, head and cam, with race preparation limited to a home-made aluminium bonnet and door skins, and the interior gutted. The supercharger never reached its full potential as the relief valve spring lifted constantly (too light). The photo was taken at the Warwick Farm (Sydney) esses during a Sports Sedans practice on the 2nd of May 1970. Bill can be seen thrashing the Torrie at the same meeting in the last few seconds of the 8mm video clip here: http://www.youtube.c...h?v=jjgNQy6YIRk. Bill competed at this circuit the following day at the Royal Automobile Club Trophy event in the closed sports sedan race. He was slow off the grid when the supercharger blew back, finishing eleventh after passing a half dozen cars during the ten-lap event. Whilst Bill was driving the Type 110 Norman supercharged GTR Torana, it still was not quick enough. Eldred’s answer was to build a Hillman Imp with a Buick Fireball aluminum 215ci V8, complete with the Type 270 supercharger and Corvair gearbox. The whole mechanical package was contained in a triangulated frame connected to the chassis by pins for easy removal. The Hillman was test driven for a few yards (snapping the input shaft in the process), though sadly was not completed prior to Eldred becoming ill and passing away. The Type 270 supercharger survived, and is currently owned by Mike Norman. Mike Norman also drove an ex-PMG FE panelvan (repainted from red to grey) with a Type 65 supercharger around 1964-1965, and a 350 supercharger fitted to a 122ci SOHC Triumph Dolomite Sprint (I currently own the supercharger). |

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #248 on: September 02, 2014, 09:40:17 PM » |

0

|

12. Other PursuitsNorman and Nancy pursued a wide variety of interests, including literary. Eldred for example had written a six-article series for the Motoring News section of Adelaide’s News in 1952 (including How Compression Operates). He also tried his hand at writing at this stage, completing (though not publishing) The Memory Beam (an alien story with brain erasing) and Coffins in the Sky. Nancy worked as a journalist and art critic for the Adelaide News, and became a poet and novelist. Her most famous trilogy All The Rivers Run, was published in 1958. The story was adapted to a television mini-series starring Sigrid Thornton and John Waters which ran from 1983 through 1989. Nancy also wrote The Dancing Bough (1957), Time, Flow Softly : a novel of the River Murray (1959), Green Grows the Vine (1960, with a dedication for Eldred), But Still The Stream: a novel of the Murray River (1962), The Sea Ants: and Other Stories (1964), North-West by South (1965), Brown Sugar (1974), Queen Trucanini (1976, with Vivienne Rae Ellis), Nin and the Scribblies (1976), Mister Maloga: Daniel Matthews and his Mission, Murray River, 1864–1902 (1976), The Noosa Story: A Study in Unplanned Development (1979), Forefathers (1983), The Lady Lost in Time (1986), A Distant Island (1988), The Heart of the Continent (1989), River's End (1989, with Leslie McLeay) and Marigold (1992). Her poetry includes The Darkened Window (1950), whilst she also authored the play Travellers Through the Night and edited the Jindyworobak Anthology (1950). Nancy became prominent as a conservationist and Aboriginal Rights activist. An active member of the Sporting Car Club of South Australia, Eldred often took his children to events, leaving Nancy free to write. During a trip to Darwin Eldred had swapped a bottle of whisky for a .45 caliber sub-machine gun. An earlier purchase of a truck had yielded crates of ammunition. During construction of the Sporting Car Club of South Australia's 0.4-mile hill-climb track at Collingrove in the Barossa Valley, Eldred used the sub-machinegun to hammer soil in around fence posts. Another version of this tale is related by Geoff Berry in With Casual Efficiency. Berry assisted in the construction alongside Eldred, and, indicates that the gun was used to dig holes in order to place gelignite for blowing up stumps and rocks (rather than tamping down fenceposts). For years the case of hundreds of bullets lay open in the shed for the three Norman children to play with, together with a quantity of dynamite which Eldred finally disposed of when it began to weep nitroglycerine. Eldred was one of the foundation directors of Brooklyn Speedway South Australia Ltd, the company which built and operated the Port Wakefield track from early 1953. In 1958 Eldred would gift two hundred and fifty of his shares in the Brooklyn Speedway Company to the Sporting Car Club of South Australia. The image below, taken from With Casual Efficiency, shows (from left) Andy Brown, Gavin Sandford-Morgan and Eldred at the Easter 1963 meeting at Port Wakefield, where Sadnford-Morgan had won the Sports Car scratch race.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #249 on: September 02, 2014, 09:40:55 PM » |

0

|

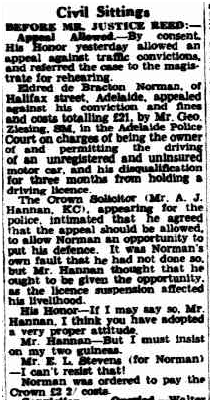

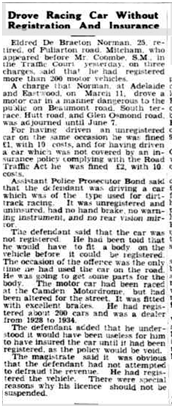

Stories abound of how Eldred outpaced police as he tested cars on the road between his Adelaide workshop and his Hope Valley home. The police would be on his doorstep moments later, looking to nail him for driving an unregistered vehicle. "Oh, no, it hasn't been running at all... not for a couple of days" he would tell them. Feeling the warmth of the engine cover, the police exclaimed that it retained its heat well and departed. Eldred soon learnt that it wasn’t a bad idea to hose down the bodywork after such a run. His tactics were not always successful though, as the clippings from the 11th of May 1938 and 3rd of October 1946 edition of Adelaide’s Advertiser below show.   Eldred was also booked for speeding over an intersection (with fines of £1. and 10/ costs in November 1939), and with driving an unregistered car (no penalty, though slugged with 7/6 costs) in August of that year. In one of the incidents above, the Assistant Police Prosecutor noted that “Practically every regulation In the Traffic Act has been broken”. In another incident, when the magistrate shook his head and said, "What will I ever do with you? You come in here so often it’s a waste of the court’s time" he quickly answered back: "Could I have a monthly account?". In 1962 the South Australian Police booked Eldred for low level speeding when he was heading to a race meeting, most likely to watch the first Elfin Formula Junior in action. Eldred was outraged to be caught by the state's first Police radar - he considered it to be unsporting of the Police. He went to enormous trouble in an attempt to prove that the radar was inaccurate. He even went to the extent of obtaining the exact same model of radar unit and spending weeks testing it for potential flaws by attaching strips of reflective alluminium to rotating wheels. When his court day arrived Eldred wheeled the radar unit into the court, to the consternation of the Police prosecutor. The magistrate found the offence proven but did not resort to a conviction, due to Eldred's GOOD DRIVING RECORD! Eldred’s larrikin nature and engineering practicality are also demonstrated in the following anecdote from Steve Tillet. At a South Australian Sporting Car Club meeting Eldred had been told that Steve’s firm were installing a camshaft grinding machine. Eldred indicated that he had a Holden camshaft, and that as Holden spares were fairly sparse he wanted the camshaft ground. Steve went to Eldred’s Hope Valley home at the appointed time to pick up the camshaft, and Eldred started looking for it. As they walked through the house he noted that Bill, then about three years old, was walking up and down on the piano keyboard. "That kid's got an ear for music," Eldred told him. Finally, with no sign of the camshaft, Eldred called out to Nancy and asked if she'd seen it. "Is that that metal stick with the lumps on it?" she responded. "Yes, that's it," said Eldred. "Okay, I was using it to break those rocks out the front...". Nancy had a pile of rocks she was using for lapidary, so the camshaft was lying covered in dirt in the pile. Eldred picked the lump stick up and handed it to the cam grinder, "A bit more lift and a bit more overlap and they'll never catch me in the trials!" he said. |

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #250 on: September 02, 2014, 09:42:12 PM » |

0

|

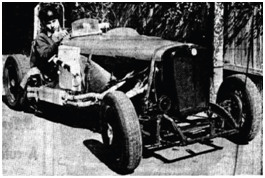

13. Larrikin AnecdotesSome other Eldred Norman anecdotes include: • As a child, Eldred’s father William operated a steam engine at home. The boiler pressure relief valve stuck, allowing the pressure to build to an alarming level. Being frightened to approach the boiler he rushed upstairs, took aim with a rifle and shot off the valve. In a separate incident, Nancy’s .22 rifle was employed during a trip to Fannie Bay (near Darwin, Northern Territory) to hunt a rat. The near dark conditions almost lead to the loss of a toe. Back home, Eldred’s issue of feral cats was solved by use of a length of guttering. The guttering was sealed at both ends and a rifle pointed down the length. Some milk bait and a length of string attached to the trigger led to the demise of many moggies (the exact number being subject to much speculation). • On one interstate trip, towing a race car on the trailer behind the family Zephyr sedan Eldred proposed to travel with the least number of stops. Just before departing, Eldred purchased 200’ of rubber piping, draping it around the interior of the tow car. He reasoned it would be cold travelling at night, and connected the piping to the cars radiator to act as a heater, as well as to a container under the dash for warming beans. The Falcon car used for the Norman’s overseas trip had been fitted with a similar heater to allow them to stop for a cuppa en-route. • Eldred’s love of warmed beans was matched for his love of chocolate. Whilst an ice chest was used inside the house, a dedicated kerosene fridge was located outside for the chocolate. • On another interstate racing trip, Eldred’s packing must have been rushed as he forgot his shoe laces and the collar stud for his good shirt. He showed his ingenuity by arriving at the celebration dinner discreetly using welding wire for his shoes, and a nut and bolt for his collar. • Eldred’s workshop office air conditioner car radiator fed chilled water from a drum of ice, electric fan. Eldred bough quality cotton handkerchiefs by the carton from David Jones, used them for wiping dipsticks and cleaning sumps then discarded them in a corner. • When Eldred wanted to better enjoy his home movies, he built a bigger screen… around sixteen feet wide and ten feet tall. The screen was set-up in the front yard, with the projector on the verandah some eighty feet away. • From Ray’s article: “His workshop was to become the centre of his activity for some two decades. It was here he became the first person in Australia to put a racing car into series production. This started with a conversation with Steve Tillet, who frequently met Eldred for lunch. Many of Tillet’s stories about Norman commence with “I met him for lunch one day…” and continue with a story that reveals that Steve had to wait around and in doing so noticed things in the vicinity. In this case it was five Morris 8 van rolling chassis at the agents Motors Ltd. “They’d make a nice little racing car” He told Eldred “and the 4.5 diff ratio would be just right”. By 11 that night he had bought them for £200 each, the first chassis had been shortened and he was waiting for Snow Young to come around the next day to build an alloy body. According to Steve, they were quicker than an MG and sold for £450 each. Tillet recalls that David Hopkins bought one and Bill Hayes raced one at Woodside, but the last car was not finished. It had the front axle split and converted to swing axles, the rear end was coil sprung and had trailing links, and it hung around until bought by a certain youngster named Garrie Cooper in 1955. Known as the Cooper Butler (Norm Butler was to buy it and race it), Cooper never called the completed car an Elfin, but it started him on his way.” Cooper went on to build three Cooper Butler vehicles (not to mention developing Elfin). It is possible that the first one, built from Eldred’s Morris chassis, is shown in sepia below.  The second (red) Cooper Butler, based on an Austin A40 is also shown.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #251 on: September 02, 2014, 09:42:44 PM » |

0

|

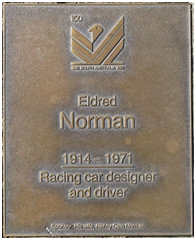

• Ray also relates the following tale, one that Eldred favoured sharing: “Like the time he got bogged in Western NSW. Hoping for a passing motorist to help got him nowhere, only one T-model going by while he was there, and it was driven by a farmer with his hat down over his eyes and his pipe upside down. There were however cattle in an adjacent paddock. Cutting the fence, he rounded up one and used fencing wire to hitch it to the car. It wouldn’t budge. More fencing wire was wrapped around one of its horns, then attached to a plug lead. The animal moved, got him out of the bog, and got itself jammed between two trees.” 14. The Passing of Two Legends.Eldred was sadly taken by lung cancer on the 28th of June 1971 at Noosa Heads. Nancy passed away at Noosa on the 3rd of July 2000. Both Eldred and Nancy were recognised in a number of ways. Nancy, pictured below, was appointed a Member of the Order of Australia (AM) in June 1984 in recognition of services to Australian literature.  The Canberra suburb of Franklin includes Nancy Cato Street. The Jubilee 150 Walkway is a series of one hundred and fifty bronze plaques set into the pavement of North Terrace, Adelaide. It was officially opened in December 1986 as part of the celebrations commemorating the 150th anniversary of the founding of the state of South Australia. The plaques contain the names and deeds of one hundred and seventy people who made major contributions to the founding and development of South Australia. The plaques are arranged in alphabetic order. Eldred’s plaque, shown below is located between the Art Gallery Of South Australia and the University of Adelaide.  Whilst Eldred was nominated for Life Membership of the Sporting Car Club of South Australia in 1958, this was not granted as he had not been a member for ten unbroken years as per the constitution (his pre-war membership period apparently did not count). In 1963 Eldred financed the club’s trophy for Meritous Service, with the proviso that it was not for achievement in motor sport. The resultant Eldred Norman Perpetual Trophy has been awarded annually ever since. Cheers, Harv (deputy apprentice Norman supercharger fiddler). |

|

|

|

|

Logged

Logged

|

|

|

|

Professor Grey

Junior Member

Offline Offline

Model: FC

Posts: 98

|

|

« Reply #252 on: September 03, 2014, 09:43:12 AM » |

0

|

Jeez mate! Only one question..... WHEN DO YOU BLOODY SLEEP  Cheers, Prof. |

|

|

|

|

Logged

Logged

|

You don't get this old by accident.

|

|

|

|

Harv

|

|

« Reply #253 on: October 25, 2014, 02:31:03 PM » |

0

|

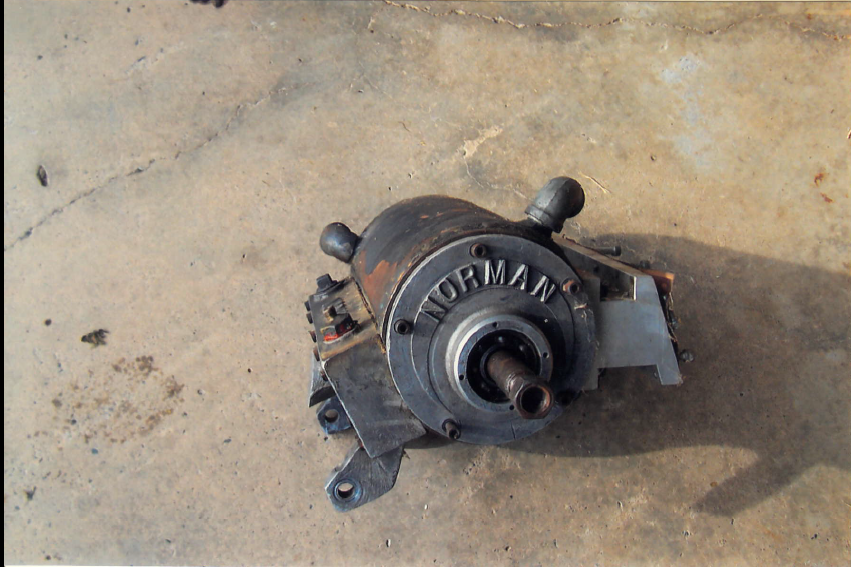

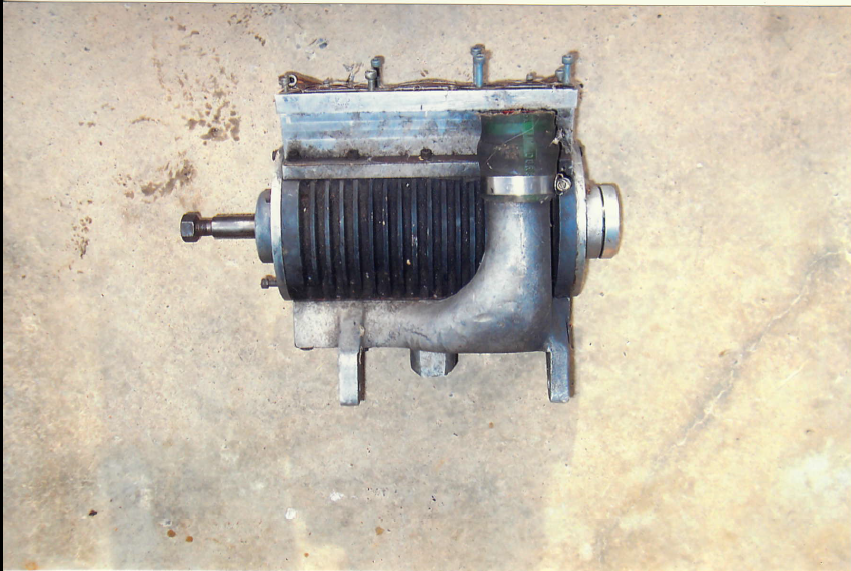

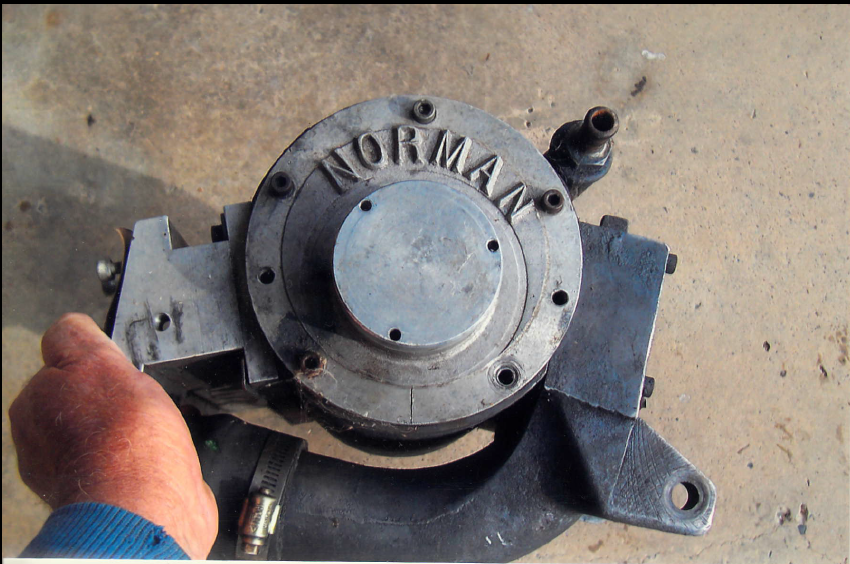

Ladies and gents, Some interesting photos to add to the thread. The two photos below were taken by the late John Brown, and show Bill Macintosh’s Norman-supercharged FJ Holden in Gympie, Queensland 1988.  Looks to be either a Type 65 or Type 70, running twin SUs. Does anyone know anything about the car, or where it is now? I feel somewhat guilty about the four photos below. The Norman shown belongs to John Brown. I had been having a good conversation with John over his Norman, though typically of me I kept getting sidetracked into other early Holden go-fast gear. When I visited and saw John’s Norman, I was foolish enough to not have taken a camera with me. John promised me that he would take some photos, which he did in the week or so before he passed away. Its typical of John that he went well out of his way to do this for me. RIP mate, and thankyou for the photos.     John’s Norman is an early water-cooled Type 65, with cast iron casing, steel rotor and aluminium end plates. This is the same as the Type 65 run in Bob Moule’s Bobcat humpy, which is currently living in Anthony Harradine’s EJ Holden Premier. Note that the water jacket nipples are offset, with one at either end of the casing. This is different to later Type 65s, where the nipples are in the middle of the casing and aligned. John’s Norman has the “NORMAN” cast outlet manifold, with the swoopy u-piece to bring the supercharger outet back up towards the bonnet, running between the engine and supercharger. This manifold uses a hose connection to run to the airhorn of the standard inlet manifold. Note the nipple on the discharge plenum for measuring boost. The mountings for John’s supercharger locate the unit low on the passengers side of the block, effectively replacing the generator. The generator is then located up high, close to the bonnet. John’s supercharger has been fitted with an aluminium box plenum inlet manifold... not sure what carbs it has been set up for. The drive end shows an open-race ball bearing. Most of these have been replaced over time with sealed bearings, so John's may not have been worked on for a while. The non-drive end of John’s Norman is blanked with aluminium plate. Cheers, Harv (deputy apprentice Norman supercharger fiddler). |

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #254 on: October 29, 2014, 02:39:02 PM » |

0

|

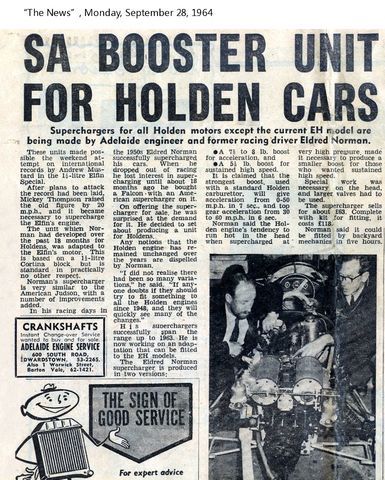

Ladies and gents, Another newspaper clipping has surfaced (with thanks Kevin – appreciated) from Adelaide’s The News newspaper of September 28th 1964:  Some interesting info here. The main photo shows Mustard’s twin-Norman supercharged Elfin, the subject of the Bluebird/Elfin landpseed trials anecdote I posted here a while back. The gentleman on the left of the photograph is Andrew Mustard, though I am not sure who the person on the right is (could be Eldred, though I have never seen him in eyeglasses before). The article also shows Eldred busily working away on supercharger fitments for early Holdens, including the new EH. Note that the model indicates Eldred is making two versions, using the standard carb: a) 7 ½ to 8 psi boost for acceleration, and b) A 5½ psi boost for sustained high speed. This is the period of time where Eldred was making the Type 65 and Type 70 superchargers (rather than the later Type 45/70/90’s). Cheers, Harv (deputy apprentice Norman supercharger fiddler). |

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #255 on: November 01, 2014, 03:31:10 PM » |

0

|

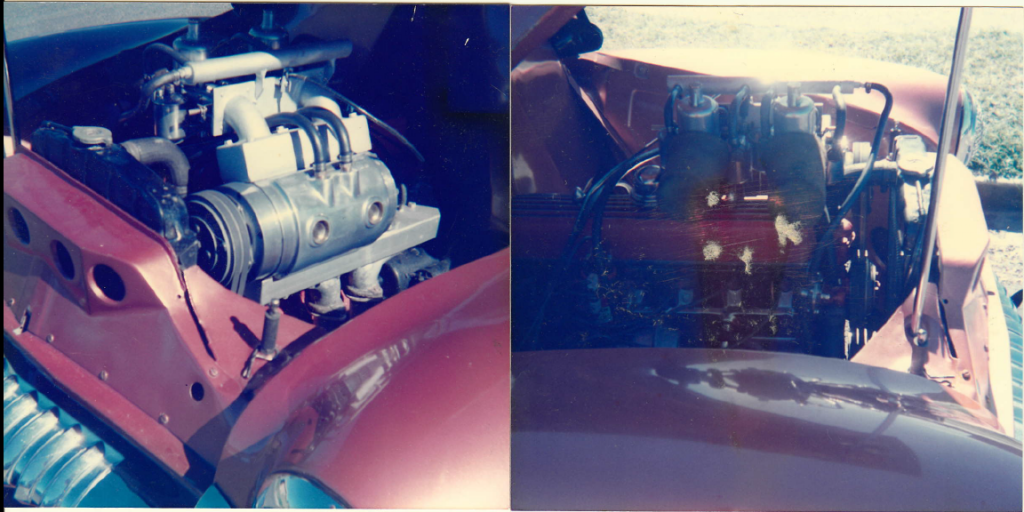

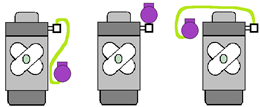

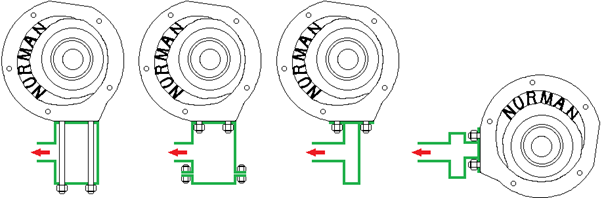

Ladies and gents, In the post below, I am going to cover some of the things to work through in getting a manifold made up for your Norman supercharger, including Interpreting some of the guidance from Supercharge! and Supercharged! Design, Testing and Installation of Supercharger Systems. Before I launch into it, I’d like to thank Pete Mallaby, who made up the manifold I have been working on. Pete has taken my poor description and crappy details and made a truly beautiful piece of steel. Any issues with the manifold (like my bad measurement… as we’ll see) are my fault alone. For anyone wanting a good bit of steel (or ally) made up, I would highly recommend Pete’s work. Contact details for Pete’s business are: Mallaby Sheetmetal 65 Piercefield Rd, Mt Thorley NSW 2330 PO Box 1, Broke NSW 2330 Telephone: (02) 65746300 Facsimile: (02) 65746311 Email: admin@mallaby.com.au The manifold should be kept as near to the cylinder head as possible. Longer distances makes top end performance suffer, although does not affect mid range torque. Some early grey motor Norman superchargers were mounted in place of the generator, as per the left hand image below.  This made use of the standard GMH inlet manifold, and a length of rubber piping. Later grey motor Norman installations mounted the supercharger on a custom box manifold, as per the image in the middle. This positioning was also used by Mike Norman for Holden red motors. Red motor superchargers made by Eldred used the lineup shown to the right above, where the supercharger is mounted on the drivers side of the engine and a hose/piping used to go over the rocker cover to the standard inlet manifold. Whilst the left and right image line-ups give some flexibility in supercharger location, the middle image gives the shortest distance. It does however mount the supercharger very high, and can cause bonnet clearance issues. For the middle option, the most satisfactory manifold (according to Eldred) is a box manifold feeding by short stub pipes direct into the inlet ports (the middle image above). Eldred recommended making the box of 3”x2”x 10-gauge tube (the modern equivalent to this is 50mmx75mmx4mm RHS). Bear in mind however that the early superchargers are very heavy… an alloy-case Type 65 with a 2” SU bolted to it weighs 20½kg! This means the box needs to be fairly substantive to prevent bowing. The Norman supercharger is provided with a series of tapped holes in the casing, which are in the footprint of the supercharger mounting face. This makes it difficult to bolt to the box. One option is to run the bolts (studs) right through the box, as per the left hand image below.  |

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #256 on: November 01, 2014, 03:34:20 PM » |

0

|

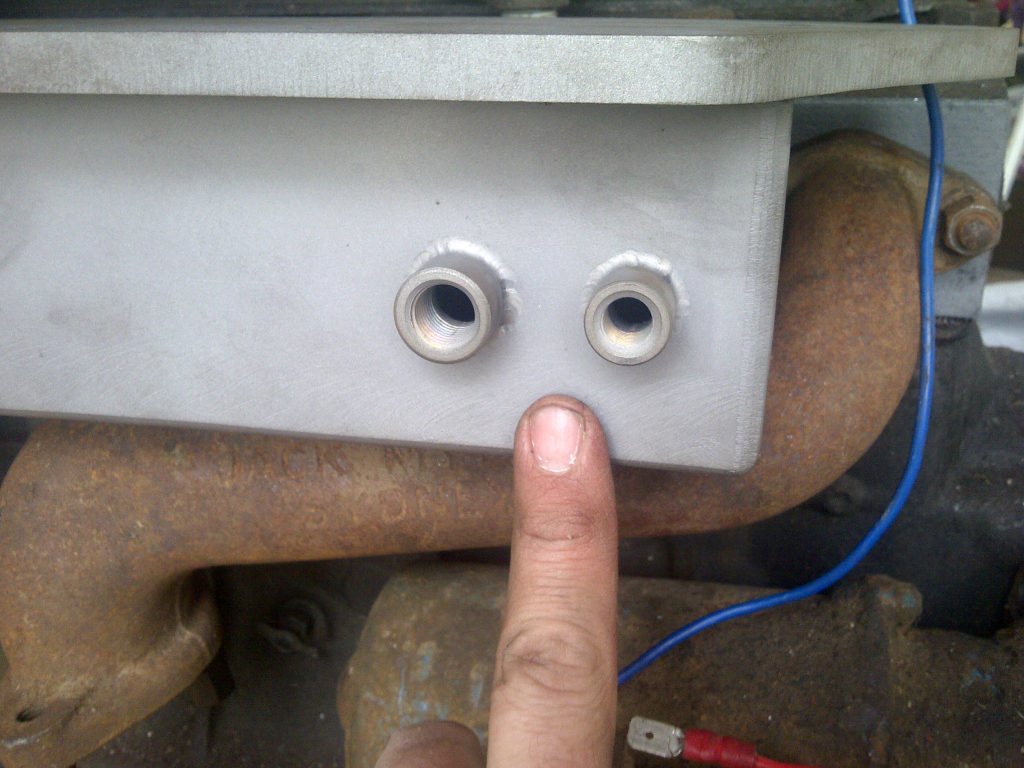

However, this option means that the bolts must be sealed to the box with washers and/or sealant, and will be prone to leakage (especially following a blower bang). Another option, as shown in the second image from the left, is to split the box to allow access inside. The box top half can then be bolted to the supercharger before the two halves of the box are bolted together. This process however gives a large flange joint in the box, which would be even more prone to leakage. It also places the nuts inside the box. Whilst the nuts can be locked or safety wired, it is not too comfortable a place to have them… a loose nut sucked through the engine is no laughing matter. An easier method is to top the box with a flange, as per the third image. This avoids leak-prone joints or piston-destroying nuts inside the box. Note that the Norman supercharger can be rotated and mounted sideways to increase bonnet clearance, as per the image to the right. Provided the carburetor-to-supercharger manifold still mounts the carburetor(s) in the correct orientation then no loss of performance results (the Norman does not know or care what way it is turned). The third image above is perhaps the neatest solution, and is the same one as used by Eldred for his grey motor manifolds. A word from the wise – when specifying the width shown with a red arrow in the image to the below, make sure that you allow enough spave not only for the bolts to straddle the box, but also the bolts heads.  Being foolish, when I had the manifold shown below made I forgot to allow for the bolt heads (and later felt like a right proper tool). Whilst allen-head capscrews only have small heads, even they take up space.  The dimension shown by the red arrow above needs to be a touch under 2” for Type 65’s, and will vary with different superchargers. You’ll note in the image below that I had to make an alluminium sandwich plate to correct my mistake.  |

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #257 on: November 01, 2014, 03:34:52 PM » |

0

|

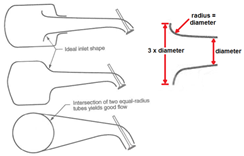

The plenum (or box) part of the manifold serves two purposes. Firstly, it takes the discharge flow of the supercharger and distributes it to each of the cylinder head ports. Secondly, it acts as a pulsation dampener, smoothing out the flow (remember that our positive displacement Norman supercharger pushes out discrete “packets” of discharge every time a vane passes the outlet… the engine cylinder head valves equally cause pulses as each opens and closes). According to Eldred in Supercharge!, the manifold plenum volume should have a total capacity equal to about half the swept volume of the motor (for our 138ci Holden grey motor this would be 69ci or 1130mL). Corky Bell ( Supercharged! Design, Testing and Installation of Supercharger Systems) is a bit more generous, indicating that the plenum should be at least as large as the swept volume (138ci or 2260mL). There is a balance here though in that the bigger the plenum, the more air/fuel mixture is present… and the bigger the explosion during a blower bang. The manifold I had made up has an internal volume of 106inch3 (120inch3 if you include the runners), or some 87% of the grey motor swept volume. This is a good balance between pulsation dampening and minimizing a blower bang. It’s a good idea to weld some nipples onto the manifold to allow connection of boost gauges etc – one ¼”NPT and one 1/8”NPT nipple is a minimum.  Whilst square-end pipe stubs welded to a section of RHS will work, the plenum to runner transition should be made as smooth as possible. Ideally, a bell shape can be made into each runner with the dimensions as shown in the image to the right.  |

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #258 on: November 01, 2014, 03:35:43 PM » |

0

|

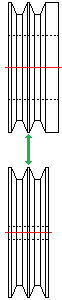

We will want to mount the relief valve on the manifold. The relief valve should be as large as practical and as close as possible to the supercharger outlet. Eldred recommends one at either end of the manifold. The box “lid” (or walls) will mount the relief valve, often achieved by drilling and tapping studs into the top of the box. The relief valve studs I will show below are ¼”-28 UNF thread. Good engineering practice is to engage the threads by 1½ times the bolt diameter, or in this case 3/8”. Making the box top 3/8” thick is a bit heavier than Eldred’s 5/32”, but it does mean that we can remove substantive amounts of steel (for more than one relief valve, or for tapping boost pressure gauges and water injection) without weakening the manifold. An alternative is to use a thinner lid, together with some nutserts, a thick mounting boss/compensating ring or to weld the relief valve studs on. Of note, if you are making the supercharger manifold yourself you will have opportunity to weld/fit/fiddle/cut/weld/repeat to your hearts content. If you are having the manifold made by an outside shop (and your welding is as poor as mine), your ability to rework the manifold is limited. A key dimension that is painful to estimate is the exact location of the supercharger in space. A little too far forward or back and the pulleys will not line up. Whilst they can be shimmed, it is a lot easier if they don’t have to be (remember that driven pulley location on the Norman can sometimes affect drive end rotor clearance…painful to fiddle with). To solve this, it is recommended that the manifold top plate/lid/flange be made “closed” initially (at least if a workshop is making the manifold for you). The manifold is then bolted to the engine, and the supercharger sat in place. The supercharger can then be moved backwards and forwards until the drive and driven pulleys are aligned. Allignment can be checked by running a straight edge (steel rule, or a long spirit level) across the face of the pulleys. There is a pretty fair chance that the drive and driven pulleys are a little bit different (for example the belts spaced apart slightly differently). The best reference point to use (i.e. the point to see is “lined up”) is probably the midpoint between the two belts on both pulleys (rather than the pulley faces), as per the green arrow on the diagram below.  This will require you to measure off the straight edge onto the pulley edge. The supercharger position is marked onto the manifold, and then the manifold removed. The hole for the supercharger to pass air/fuel into the manifold can then be cut out, and the mounting holes drilled. This gives excellent pulley alignment without having to shim the pulleys.   |

|

|

|

|

Logged

Logged

|

|

|

|

|

Harv

|

|

« Reply #259 on: November 01, 2014, 03:36:18 PM » |

0

|

Another word from the wise. Mike Norman’s superchargers mount through rails cast into the supercharger, which are fitted with steel inserts. These are pretty square, as they are made by extrusion. Eldred’s superchargers however are individually drilled. Experience has shown that the holes are not all that square. One way to transfer the exact hole location to your new manifold is to use some transfer ink. To do this, clean both the manifold and the supercharger faces, then paint the supercharger face with engineer’s blue (for example Dykem 75182 Hi-spot Marker). This is a paste that is easy to spread, and does not dry out for months. It is used in industry (where two parts are to be mated together) to detect high spots on bearings, gears and other close fits. When the two parts are pressed together, the footprint of the supercharger should transfer to the manifold, showing exactly where the bolt holes are. The footprint can then be marked onto the manifold with a scribe and centrepunch. The engineer’s blue can then be cleaned up with some kero.  Sadly, when I tried to do this it is evident that the Norman gasket face is nowhere near flat enough to transfer properly (it will need some good thick gaskets). After cleaning off all the engineers blue (I had blue fingers for days), I had to manually measure out each bolt hole from a reference point, estimating centres. If an engineering shop is making the manifold for you, they may well need the actual supercharger to work from. Finally, bear in mind that the manifold and supercharger is going to be quite heavy, putting a considerable load on the cylinder head to inlet/exhaust manifold bolts. To prevent sagging over time (and hence leaks), some bracing is required. I made up some support braces to run from the manifold to the cylinder head bolts, using some 20x5mm flatbar.  Whilst two braces are probably adequate, in theory you can mount many more on the cylinder head bolts. The braces (one flat, one S-shaped) simply bolt up to the supercharger manifold at one end and fit under the cylinder head bolts on the other. Of note though is that when the 5mm thickness of brace is put under the cylinder head bolt, the bolt only bearly engages some thread before tightening (if you try to tighten the cylinder head bolt back up to 65ft/lb, the bolt slips due to too few threads engaged. This is because the GMH cylinder head bolts have a very short thread length (which is why I ran out of thread). The idea behind this is that you only cut enough thread to do the job – any unengaged thread acts as a localised stress riser, leading to fatigue failure of the cylinder head gasket joint. As an aside, the GMH bolts are also reduced in diameter (they should be 7/16” diameter, but are less than that) to ensure that all the remaining threads are fully engaged. This reduces the bending stiffness of the bolt, increasing fatigue strength. To solve the short bolt problem, remember that GMH made both “long” cylinder head bolts (part number 7401119), and “short” ones (part number 7401120) for the grey motor. The bolts on the supercharger side of the cylinder head (passengers side) are the short ones (7401120), and are 7/16”-14UNCx3½”. I didn’t measure a longer bolt (from the drivers side of the cylinder head), but from memory the longer bolts are ½” longer (7/16”-14UNCx4”). The simple solution is thus to find a spare “long” bolt and use it. |

|

|

|

|

Logged

Logged

|

|

|

|

|