|

mikey

|

|

« Reply #20 on: February 28, 2009, 04:59:55 PM » |

0

|

John,

The cut-out severely weakens the the floor (and body generally).

Where is your strengthening coming from.

Geoff

Hi Geoff, I don't really see why it would, it is the same size as the one in the EK automatic. Although I have put the hump in mine I have yet to replicate the cross member to the underside of the hump. So the strength would be the same. Have you experienced some problems in the past with a bigger hump perhaps? Cheers M |

|

|

|

|

Logged

Logged

|

Our Lady of Blessed Acceleration, don't fail us now!

|

|

|

|

mcl1959

|

|

« Reply #21 on: February 28, 2009, 06:27:28 PM » |

0

|

Ratbox, what is the purpose of your comment? There are always stories of people who did this and that and then you add that you wouldn't do it yourself anyway.

As a qualified mechanical engineer I can tell you quite equivocally that the removal of the structural member across the body does weaken the shell and it does not necessarily exhibit as immediate failure when you do a burnout etc.

What happens is that the body shell flexes more than it should and stress cracks develop at pillar joints around the car. Eventual failure will occur and it may not be catastrophic, just simple cracks going right through a pillar for example. A crash is another matter and like you, I would not like to be in an accident in a car which has had strength members removed.

A certifying engineer must try to set standards of modification to not only make the vehicle safe at the time of registration, but for the life of the car. This negates all stories such as those you regale.

Having said all this - let me try to add a positive spin to this thread - there are well known methods for returning the strength to the shell after cutting this crossmember and I am sure that Red devil has considered these as part of the gearbox installation, so I would just like to say good work so far and if I can help you in any way I will be more than happy to do so.

Ken

|

|

|

|

|

Logged

Logged

|

|

|

|

FC_fer_me

vic-club

Full Member

Offline Offline

Posts: 226

baby boomers luv FC's

|

|

« Reply #22 on: February 28, 2009, 08:00:03 PM » |

0

|

I have just recieved my floor tunnel from V6 conversions and it had no strengthening underneath. After a phone call I found out that they also supply a subframe and gearbox member which strengthens the underside of the tunnel and attaches to the existing underfloor subframe. I have ordered this and will post photos when it arrives. Cheers, Jack

|

|

|

|

|

Logged

Logged

|

|

|

|

|

EffCee

|

|

« Reply #23 on: February 28, 2009, 08:06:24 PM » |

0

|

The factory EK Auto floorpan has a strengthening member that goes across the floor on the inside of the vehicle to regain the original strength. I have one of these that I will be fitting to mine and will take some photo's to show how it is done from the factory. I will post these tomorrow

Keith

|

|

|

|

|

Logged

Logged

|

Canberra, ACT F4+  |

|

|

|

EffCee

|

|

« Reply #24 on: February 28, 2009, 08:09:36 PM » |

0

|

Sorry, I should add that I deliberately sought an original pan out so that I was able to retain the original structual strength that the EK had from factory, that I had doubts about by using the CRS or similiar unit. I am not saying that these cannot be made to be of the same strength, I just didn't want the engineering issues involved.

|

|

|

|

|

Logged

Logged

|

Canberra, ACT F4+  |

|

|

|

ratbox

|

|

« Reply #25 on: February 28, 2009, 10:18:15 PM » |

0

|

mcl1959 why not ask what's the point of geoff_k comment aswell ? cause as far as i can figure red devill intended to replace what he cut out

mine was a comment and nothing more, some people like to here life experiances not just stuff that comes out of a book there's plenty of cars driving around severly compramised due to rust and the people never even know or ignore it

i don't want to argue with you as being an engineer you have far more knowledge than me

|

|

|

|

|

Logged

Logged

|

|

|

|

|

EffCee

|

|

« Reply #26 on: March 03, 2009, 10:46:42 PM » |

0

|

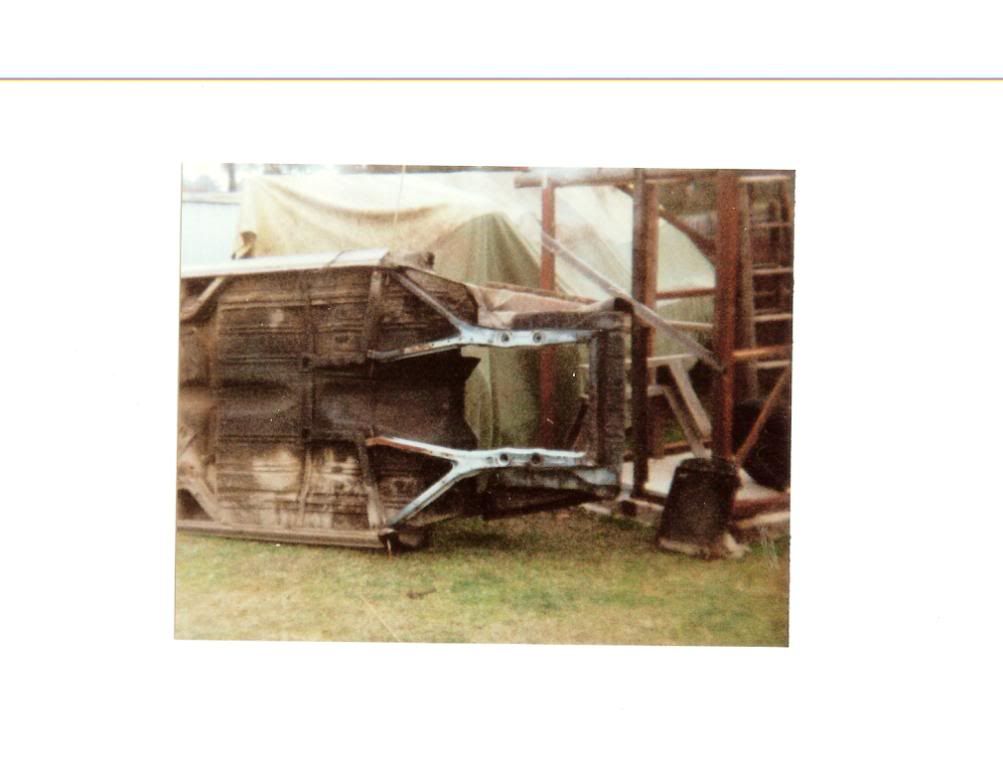

Sorry for the delay, I have attached some photo's I have of the EK Auto floorpan that I will be fitting into my FC. The first photo shows the underside where I will need to attach the subframe rails that will need to connect to the existing ones. The plan for my car is to remove the existing subframe and manufacture a section of subframe and weld that into the car. I will also be connecting the part of the subframe that runs parallel along the transmission tunnel. As one can see it also has the handbrake relay lever attached and I will be using this also.  This shot is of the floorpan from above and the brace that is on the inside of the floor is quite visible, this adds to the strength that would normally be lost when the section of crossmember is removed.  I tried to get the angle right which illustrates the how the underneath crossmember and the crossmember that fits inside the car is all held together and becomes a very strong unit, probably increasing the strength over the original floorpan.  Another shot of the floorpan crossmembers.  A shot of the internal crossmember showing how it is rolled rather than a square section.  Looking at the rear of the floor section showing the cross section of the support that would run along the transmission tunnel. I will be fabricating this section and extending it along the transmission tunnel as per the EK auto.  |

|

|

|

|

Logged

Logged

|

Canberra, ACT F4+  |

|

|

customFC

nsw-club

Guru

Offline Offline

Model: FC

Posts: 5900

Ask me about microwaving cats for fun or profit.

|

|

« Reply #27 on: March 03, 2009, 10:55:14 PM » |

0

|

I pinched this pic from Gary's wagon build up, as he also used the EK hump.  It shows how the underfloor sections run. Regards Alex |

|

|

|

|

Logged

Logged

|

|

|

|

|

NosFEratu

|

|

« Reply #28 on: March 04, 2009, 07:51:59 AM » |

0

|

Keith

Thanks for the detailed photos. I have been spending time building engines lately but planning the floor mods to van to take the V6 Chev and T700. Your photos have helped me finalise the design. Now all I need to do is roll out the MIG and plasma.

John (Nosferatu's darker side)

|

|

|

|

|

Logged

Logged

|

NosFEratu   |

|

|

|

EffCee

|

|

« Reply #29 on: March 04, 2009, 07:59:58 AM » |

0

|

John,

Always pleased to help in any way that I can. Happy fabricating!

Keith

|

|

|

|

|

Logged

Logged

|

Canberra, ACT F4+  |

|

|

red_devil

nsw-club

Senior Member

Offline Offline

Posts: 635

I love YaBB 1G - SP1!

|

|

« Reply #30 on: March 04, 2009, 10:41:25 AM » |

0

|

Hi guys we have some ideas of fabricating a rear cross member with some additional strengthening plates and brackets. Will take pic's and post along the way.Thanks again for the comments and assistance.

If someone could now just get the dollar up to around .72 I can commission the FC wagon model car project, can anyone ring the US President and put in a word about our dollar.

Red

|

|

|

|

|

Logged

Logged

|

|

|

|

|

earlyholdenfan

|

|

« Reply #31 on: March 04, 2009, 02:44:51 PM » |

0

|

If anyone needs an EK auto floor section let me know I have one from a project I no longer need.................

Located in Melbourne

Matt

|

|

|

|

|

Logged

Logged

|

|

|

|

red_devil

nsw-club

Senior Member

Offline Offline

Posts: 635

I love YaBB 1G - SP1!

|

|

« Reply #32 on: March 08, 2009, 10:35:59 AM » |

0

|

Boy seemed to have created a bit of a storm here, thanks again for the wonderful support guys all this stuff is invaluable.

Regards

Red Devil.............

|

|

|

|

|

Logged

Logged

|

|

|

|

|

mcl1959

|

|

« Reply #33 on: March 08, 2009, 06:39:51 PM » |

0

|

Here are some more photos Looking from the front  Looking from the rear shows handbrake mechanism tucked up behind crossmember  this shows another shot of the crossmember and how it goes right where the old handbrake was  from the rear shows a different angle. The crossmember is HR and the handbrake is based on HG parts  this is from the front again and shows how HR crossmember had the ends cropped and filled to fit. It looks like the bolt is loose in the photo but it is actually a hole forward of the crossmember  side shot shows that the EK crossmember pieces are wider than original FE/FC under floor member. It also shows a special extension piece I made for the original front handbrake cable.  |

|

|

|

« Last Edit: March 08, 2009, 06:50:31 PM by mcl1959 »

|

Logged

Logged

|

|

|

|

FC_fer_me

vic-club

Full Member

Offline Offline

Posts: 226

baby boomers luv FC's

|

|

« Reply #34 on: March 09, 2009, 12:04:19 PM » |

0

|

|

|

|

|

|

Logged

Logged

|

|

|

|

red_devil

nsw-club

Senior Member

Offline Offline

Posts: 635

I love YaBB 1G - SP1!

|

|

« Reply #35 on: March 27, 2009, 08:39:28 PM » |

0

|

|

|

|

|

|

Logged

Logged

|

|

|

|

FC427

nsw-club

Guru

Offline Offline

Model: FC

Posts: 2457

I love YaBB 1G - SP1!

|

|

« Reply #36 on: March 27, 2009, 08:46:56 PM » |

0

|

Looks good John  Did you check your pinion angle before finalizing the height of the rear gearbox mount   .......FC427...... |

|

|

|

|

Logged

Logged

|

As I lay rubber down the street I pray for traction I can keep, but if I spin and begin to slide please dear god protect my ride

|

|

|

red_devil

nsw-club

Senior Member

Offline Offline

Posts: 635

I love YaBB 1G - SP1!

|

|

« Reply #37 on: March 27, 2009, 08:54:38 PM » |

0

|

to the mm, everything you see is loose just threw together for these shots, cant wait to drive her again after four and half years, bloody model car business has taken over my life, never mind.

Red devil.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

mcl1959

|

|

« Reply #38 on: March 27, 2009, 09:21:02 PM » |

0

|

That looks awesome - can't see you having any problems at all with that set up.

Ken

|

|

|

|

|

Logged

Logged

|

|

|

|

FC427

nsw-club

Guru

Offline Offline

Model: FC

Posts: 2457

I love YaBB 1G - SP1!

|

|

« Reply #39 on: March 27, 2009, 09:21:38 PM » |

0

|

John did you set it up so the diff angle 1or 2 degrees different to the gearbox   ........FC427..... |

|

|

|

|

Logged

Logged

|

As I lay rubber down the street I pray for traction I can keep, but if I spin and begin to slide please dear god protect my ride

|

|

|

|