A couple of tips for those about to Modify (experience from motor trimming)

1. Running a bench seat and you want to fit seatbelts? a. If you are re-trimming your bench seat, it would be wise to cut the ends of 2 of the base springs that connect the base to the centre bar that runs through the seat at roughly 1/3 and 2/3 positions. Otherwise the modern plastic buckles are a bugger to fit through and are often damaged or scratched in the process. If you are not retrimming, the back flap will need to be un-hooked and more care will be needed when cutting the springs.

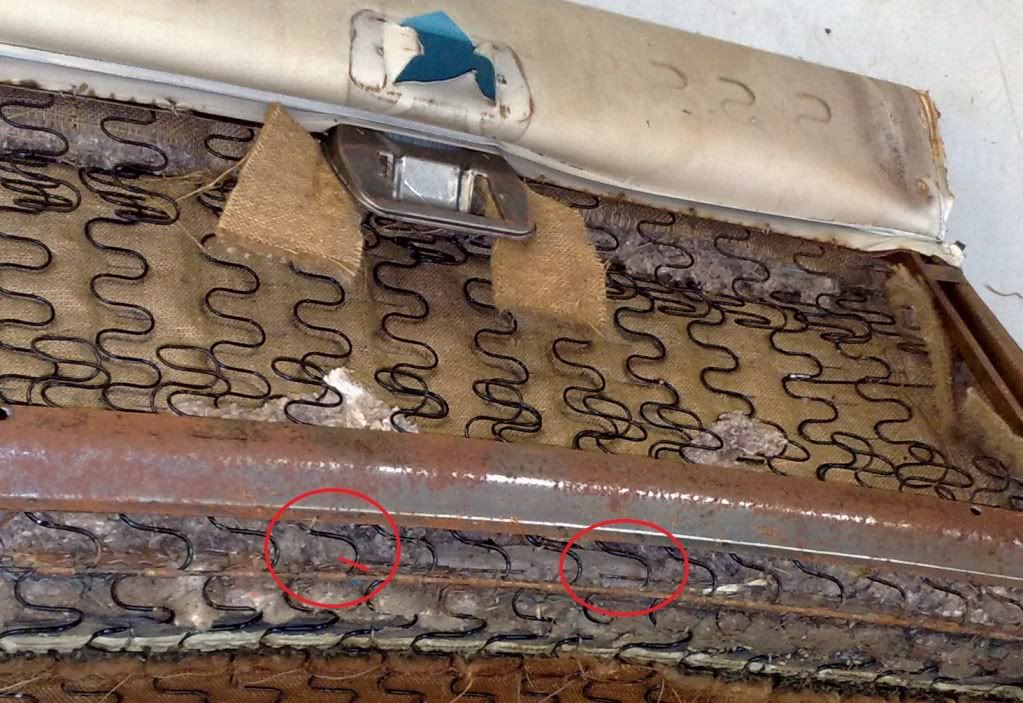

The circles show approximate spring ends to cut, the line shows where to cut, you need to leave a little bit of the spring curving up or the clamp that holds the spring may come off. After cutting the end slides out of it's bracket and the exposed part still ont he seat will need covering or padding to stop it catching the seat belt.

b. Get you trimmer to add holes in the seat cover to allow the buckles to pass though, I generally reinforce the holes with a piece of vinyl glued to the inside, then stitch around the hole for extra insurance and neatness.

2. Modifying the trans tunnelIf the floor pan is remaining basically FE/FC and you are just modifying the trans tunnel, use an EK Hydramatic trans tunnel or an aftermarket one from someone like Waddingtons or CRS. This will allow you to buy an EK Hydramatic molded carpet rather than to have something custom made up.